#Techtextil 2019

ITA at Techtextil 2019

Ambient Lighting - Demonstrator Light Textiles

With the Demonstrator Light Textiles, ITA shows an illuminated textile by using light-guiding fibres and polymer optical fibres (POF). This is ideally suited to design illuminated surfaces in the interior, e.g. in the automotive or home sector. This textile solution offers a flexible, drapable surface with a soft, pleasant feel in a limited space. ITA provides the fibre and process development. The key partner is Mentor GmbH & Co. Präzisions-Bauteile KG in Erkrath, Germany.

Background:

The polymer optical fiber (POF) demonstrator was developed as part of an ongoing cooperation between Mentor and the ITA. This is a research & development model which is linked to a doctorate at ITA and at the cooperation partner. This model offers ITA's industrial partners the opportunity to conduct targeted research in a specific field and to train qualified employees. Further information is available from jan.kallweit@ita.rwth-aachen.de.

Novel Energy Storage for Mobility Applications - Remote-Controlled Model Vehicle with Fuel Cell Drive

The remote-controlled model vehicle with fuel cell drive (RC-Car) is an emission-free model car with lightweight tanks and body made of fibre composite plastics (FRP). It consists of kits from Tamiya-Carson Modellbau GmbH & Co. KG and Horizon Fuel Cell Technologies Pte. Ltd.

The pressure vessels (Composite Pressure Vessel-CPV) of the RC-Car were manufactured by ITA with a new winding technology for pressure vessels with carbon fibres on a machine from Murata, Japan. The CPVs are produced by multifilament winding, which promises a higher productivity than conventional wet winding. They CPV can withstand high pressures, e.g. 700 bar, and offers significant weight savings compared to batteries. The CPVs enable emission-free, long-range, hydrogen-based propulsion that can be refuelled quickly and represents ITA's contribution to mobility and energy revolution. The CPVs contribute to a sustainable energy balance, since, for example, rare earths are not required as in battery production.

The target group for the CPVs is the transport sector. In the automotive industry, CPVs provide the basis for a lighter drive concept, as they can be charged more quickly and offer greater lightweight potential than batteries. For the aerospace sector, the new winding technology represents an alternative, faster manufacturing process to wet-willing pressure vessels. Further information is available from tim.moelling@ita.rwth-aachen.de.

Efficient Textile Production - Sports Bra

With ist new sports bra, ITA shows a newly developed innovative process for the highly productive manufacturing of three-dimensional knitted fabrics on large circular knitting machines without additional separating and joining steps. Large circular knitting is significantly faster and more efficient than flat knitting which was previously used.

The garments (here a sports bra) can be tailored seamlessly and individually to size in a single step and are thus an example of a store-factory approach, i.e. customer-specific just-in-time production in a specialist shop on site. This new process is patented and forms the basis for licensing this technology to new business fields and other industries. Further information is available from christoph.peiner@ita.rwth-aachen.de.

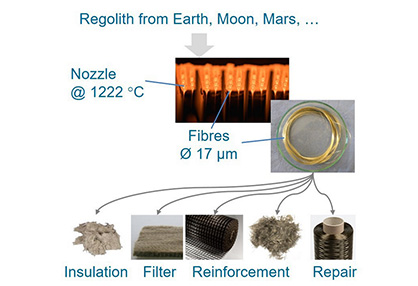

Aerospace materials - MoonFibre

Many nations are toying with the idea of setting up a lunar station and to use the moon as a source of raw materials, a research site, a stepping stone into the solar system and a tourist destination. But the transport of the material for a lunar station is very costly: to bring material from the earth to the moon costs up to 1 million € per kilogram. For a lunar station, at least 450 tons are needed.

ITA's solution: produce directly on the moon! A lot of moon rock is very similar to basalt. ITA has already developed a production process to spin mineral fibres based on lunar rock. Within MoonFibre, ITA uses this experience for the production of fibres for the reinforcement of three-dimensional structures on the basis of moon rock and produces the fibres for the construction of the moon station directly on site. ITA's approach is supported by the German Aerospace Center (DLR). In addition, the project is funded by Crowd-Funding. Further information is available from alexander.lueking@ita.rwth-aachen.de.

We look forward to meeting you at the joint stand of Elmatex in Hall 3.0, booth D05!