#Techtextil 2019

KARL MAYER is inviting the sector to an exchange of ideas at Techtextil

Highlights from the universe of high-performance warp knits

KARL MAYER is also inviting people to attend an in-house show, to be held at the same time as the fair, at its headquarters in nearby Obertshausen. This event is easily accessible by bus transfer and will be premiering a new nonwovens machine for the visitors. KARL MAYER is also a trendsetter in the field of digitisation. This manufacturer has grouped all its digital solutions under the KM.ON brand, and will also be showcasing this system on its stand at the Techtextil.

RAPID TEXTILE– the quick way to new solutions

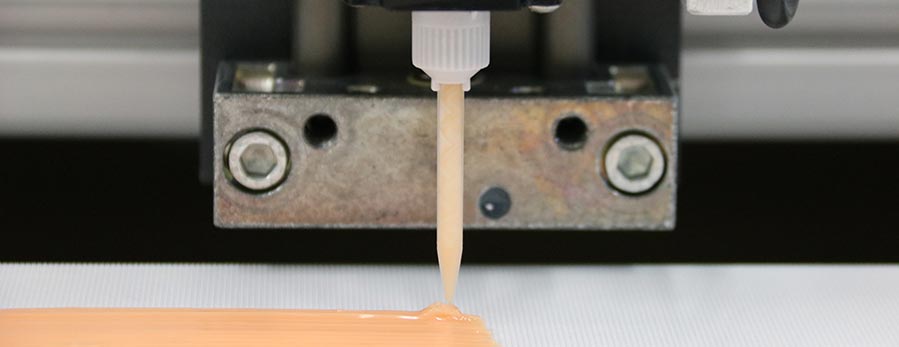

Textiles with an excellent performance and lower manufacturing costs can be produced by combining the possibilities of additive production with warp knitting technology. Examples of this include warp knits functionalised by 3D printing and these are being presented at Techtextil.

KARL MAYER has grouped together all its activities relating to the use of new technologies and innovative products under the concept of RAPID TEXTILE. They form part of the TEXTILE MAKERSPACE system, a platform that offers the space to try things out, develop new products and think outside the box.

TEXTILE CIRCUIT – the quick way to electrifying designs

Electrically conductive textiles are a hot topic at the moment and can be produced in a variety of different ways. The easiest method is to directly incorporate conductive yarns during fabric production on the machine.

TEXTILE CIRCUIT, another element of TEXTILE MAKERSPACE, shows the potential of warp knitting here. Conductive zones offering maximum flexibility in terms of geometry, dimensions and location can be produced on KARL MAYER’s multibar raschel machines. Examples include inductive charging stations and the remote control of robots, and these are being demonstrated at Techtextil.

New solutions for patterns with plastic effects

Double-bar raschel machines have become firmly established in the production of warp-knitted spacer textiles featuring a variety of designs. A new model is now enabling completely new designs to be produced, i.e. warp-knitted textiles with decorative, relief surfaces. Instead of the spacer layer, three-dimensional design elements are worked on the upper and lower sides. The designs can be shaped and positioned almost without any restrictions, and can be combined with openwork designs. This is opening up a new dimension in near-net-shaped production in particular.

Security panels made from weft-inserted warp-knitted textiles – efficient cut protection for buildings and vehicles

Burglars frequently use chainsaws and drills during attempted break-ins, but they can be stopped effectively by a new type of patented security panel with weft-inserted warp-knitted textiles in the core. On contact with the cut-resistant textiles, the rotating tools quickly release large amounts of fibres from the material. These become entangled and the tool is stopped. The highly effective security panels are also very light and can be applied very easily to e.g. security doors, armoured vehicles, vaults and cash machines.

New raschel machine for web bonding – more opportunities on the nonwovens market

A model in the new RACOP-NW series will be demonstrated at an in-house show in Obertshausen at the same time as Techtextil. This efficient nonwovens machine produces stitch-bonded nonwovens from feed webs, a technology that offers many advantages. This process produces nonwovens having textile characteristics, such as elasticity and voluminosity, which is not the case when using chemical bonding agents. Furthermore, much less energy is consumed compared to thermal processes. In addition to these general advantages, the new RACOP-NW model also offers an exceptional cost:benefit ratio. It is also extremely flexible and can, therefore, be used in a variety of applications. A RACOP-NW, 160", gauge E 14, is producing a textile for the application area heating textiles at the in-house show.