#Sustainability

PFI confirms: water-based technology from Trans-Textil and Covestro is free of animal components

+ Breathable, water-based AQUAIR® synthetics from Trans-Textil now bear the "100% Vegan" certification mark from German PFI Institute

+ No animal components or animal products are used in the product as a whole, as well as in all components and manufacturing steps

+ Highly flexible product structure in terms of design, textile components and membrane systems

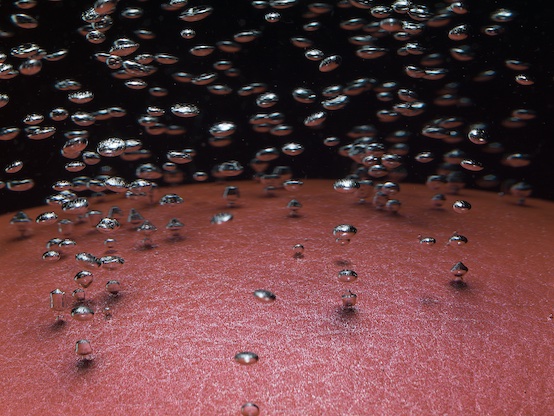

+ The water-vapor-permeable, microporous structure of AQUAIR® is based on waterborne formulation components from Covestro

"The vegan idea fits perfectly into the overall concept of AQUAIR® and is a logical further development for us," says Matthias Krings, Managing Director of Trans-Textil GmbH. Performance and responsible product design in all steps form the basis of the highly breathable overall system. The starting point is the synthetic layer, which can be individually designed in terms of color and grain.

"The microporous PU system is based on our aqueous and more sustainable INSQIN® technology, with which the production of coated textiles also requires up to 95 percent less water and 50 percent less energy compared to conventional production processes," explains Dr. Torsten Pohl, Head of Global Textile Coatings at Covestro. In combination with the technologies from Trans-Textil, this results in unique properties with a wearing comfort and functionalities that raise the standard of synthetics to a new level and are now also verifiably vegan according to the PFI standard.

Breathable, water-based AQUAIR® textile systems from Trans-Textil are based on Covestro's aqueous INSQIN® technology and have been awarded the "100% Vegan" seal by the Pirmasens Testing and Research Institute. © Trans-Textil

In addition to textile substrates, the test seal also included waterproof, breathable Topaz membrane systems based on polyurethane (PU) and polyester (PES), so that there is a great deal of creative freedom in product design with regard to structure, coloring and technical properties. The PU hotmelt systems used to manufacture the multi-layer composite products, which are applied at Trans-Textil using the high-quality and durable Point-in-Point® lamination technology, have also been vegan tested. Water-repellent properties are already integrated in AQUAIR® and no additives need to be added which are currently often viewed critically. All components and process steps are also tested according to Standard 100 by OEKO-TEX® for processing without harmful ingredients.

In a regional and responsibly designed supply chain, breathable synthetic products "Made in Germany" are created with AQUAIR® for the design of shoe components, leisure, sports and outdoor clothing, bags and accessories as well as for use in functional upholstery and furniture – even for small series or samples. The production as roll goods is the basis for an optimal use of material in the manufacture. If required, compatible Topaz tapes are available for seam sealing, which are also based on water-based formulation components.

The color and grain of the synthetic layer can be easily customized, which allows for great design freedom when used in shoe components, sportswear, bags, furniture and many other products. © Trans-Textil

Breathable, water-based AQUAIR® textile systems from Trans-Textil are based on Covestro's aqueous INSQIN® technology and have been awarded the "100% Vegan" seal by the Pirmasens Testing and Research Institute. © Trans-Textil