#Sustainability

Assessing tracer technologies to boost traceability

Today Fashion for Good and Textile Exchange jointly release “The Textile Tracer Assessment”, a detailed guide of physical tracer technologies applicable to the textile supply chain. With the increasing importance placed on fibre provenance, authenticity and production, and the growing number of technologies available, the assessment provides fashion ecosystem stakeholders with an overview to evaluate and determine which tracer technologies would best suit their sustainability and operational needs.

This guide assesses promising physical tracer technologies applicable for improving traceability verification in the textile industry. Today, there is a lack of reliable verification for fibres, materials, and finished products. Scaling and further implementation of physical tracer technologies can help to address key industry challenges for traceability and help authenticate sustainability standards and certification.

“The Textile Tracer Assessment provides much needed analysis and guidance to the textile industry players seeking clarity and direction to better understand and implement physical tracing technologies in their supply chains. This is only the beginning of this collaborative project, as more technologies mature and improved capabilities are added, it will provide the industry with an indispensable tool for traceability implementation.“ — Katrin Ley, Managing Director at Fashion for Good

The Textile Tracer Assessment is a tool for stakeholders across the supply chain from suppliers, to brands, to certification bodies, who are motivated to explore and implement physical tracer technologies to supplement existing traceability models.

BENCHMARKING KEY TECHNOLOGIES

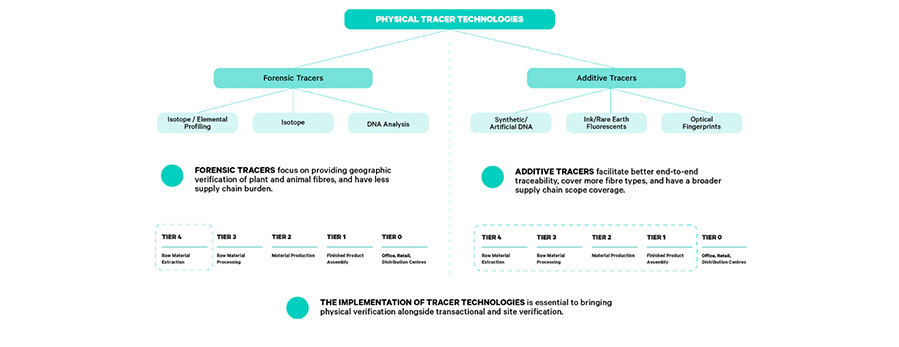

Tracer technologies are solutions that analyse the microparticle composition of fibres, materials, and finished products (forensic tracers) OR apply tracer substances at a certain point in the supply chain, to be detected later to verify origin (additive tracers).

The forensic tracer category includes isotope/elemental profiling tracers and DNA analysis tracers. The additive tracer category includes synthetic/artificial DNA tracers, ink/rare earth fluorescent tracers, and optical fingerprints (watermarks and prints).

“Tracer technologies play an important role in connecting the forensic verified physical material to existing digital chain of custody. With the proliferation of innovations in this space, we are excited to provide the Textile Tracer Assessment as a starting guide to standards, suppliers and brands wanting to better understand this landscape. We look forward to the continued alignment and collaboration with technologies to strengthen material provenance and traceability in certified supply chains,“ — Evonne Tan, Data and Technology Director at Textile Exchange

STRENGTHENING VERIFICATION IN THE TEXTILE SUPPLY CHAIN

Current chain-of-custody processes fall short in physical/material authentications which may lead to false claims and the sourcing of fibres and materials with unchecked environmental risks. This report addresses the key challenges in both categories of tracer technologies, as well as how and where best they can be applied to strengthen chain-of-custody models and fibre/material integrity.

Tracer technologies can only facilitate the flow of information, and thus should be considered within a wider context of sustainability strategy. Physical tracer technologies work best when implemented in tandem with digital traceability, and are key to supplement site-level verification, and transactional-level verification providing robust, holistic and future-proofed traceability governance.

The Textile Tracer Assessment is just the start and will continue to expand - Fashion for Good and Textile Exchange are calling all tracer technologies related to the textile industry to join the Textile Tracer Assessment so that new and existing technologies and capabilities can be updated and showcased industry wide.

https://reports.fashionforgood.com/report/textile-tracer/