#Sustainability

Massive new Chinese wastewater treatment plant employs Toray membrane modules

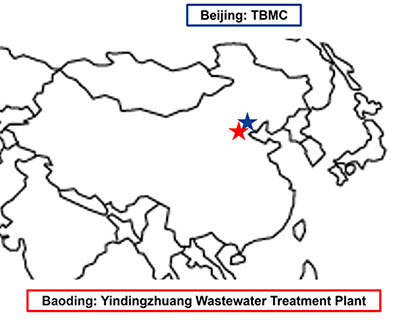

Beijing-based Toray Bluestar Membrane Co., Ltd., is supplying and providing technical services for these modules at the facility. Toray will help China enhance its aquatic environment and resolve water shortages by offering products and technical support through that subsidiary.

China built the new facility as part of a key public project to safeguard the ecology of Baiyangdian, a freshwater lake near Xiong’an New Area, a fast-expanding development hub.

China is raising its waste water treatment standards in keeping with increasingly strict environmental regulations. Switching to an advanced process employing ultrafiltration membrane modules became imperative in view of a common activated sludge process failing to match the government’s latest water quality standards.

Toray’s membrane modules employ polyvinylidene fluoride, a non-reactive thermoplastic fluoropolymer with outstanding high chemical and physical stability. The company applied a proprietary manufacturing technique to create a composite membrane structure that ensures high water permeability and minimal fouling. The membrane module pore size of 0.01 microns is smaller than those of rival offerings, significantly enhancing the quality of filtered water. China chose Toray’s modules for this public project on the strength of their exceptional reliability, lower running costs from less frequent chemical scrubbing, and results that surpass water quality standards.

The Chinese government’s 14th Five-Year Plan for Circular Economy Development has fueled demand for membrane modules to help combat water pollution. Toray can cater to such demand by drawing on the capabilities of Toray Bluestar Membrane, as well as of two other local subsidiaries. The first is Toray Membrane (Foshan) Co., Ltd., which manufactures water treatment membranes and products in Foshan, Guangdong Province. The second is Toray Advanced Materials Research Laboratories (China) Co., Ltd., in Shanghai. Toray Group units will keep collaborating to help China resolve its water issues by providing products and services that match the requirements of local customers.

Providing access to clean water is pivotal to The Toray Group Sustainability Vision, representing a roadmap to the World as Envisioned by Toray Group in 2050 and embodying

Toray Vision 2030, through which the Group seeks to achieve sound, sustainable growth. The company will do its utmost to help reach Sustainable Development Goals and other global objectives by providing superior technology and water treatment membrane products.

Profile of new facility employing Toray membrane modules at Yindingzhuang Wastewater Treatment Plant

• Location: Baoding, Hebei Province, China

• Treatment capacity: 315,000 cubic meters daily

• Operational start: July 8, 2022

• Plant Design : North China Municipal Engineering Design & Research Institute Co., Ltd

• General Contractor : Hebei Construction Group Corporation Limited

• UF System Design: Hangzhou Water Treatment Technology Development Center Co., Ltd

Toray membrane products website

https://www.water.toray/