#ITMA 2023

Retech will present various innovations at ITMA 2023

Retech as expert in drawing fibres to perfection will be showing innovations in the following fields in Milan.

- IoT in a modern heated godet

- New drive system for (super) slow speeds

- Special machine construction of drawing frames and the making of the blue thread

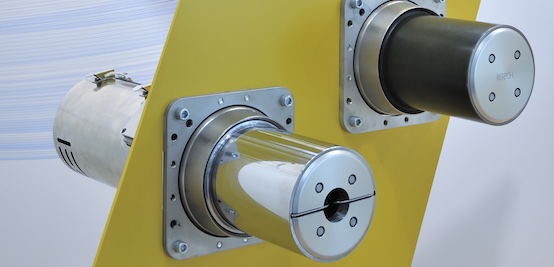

Godet rolls are essential components in the production of synthetic fibres. These heated, ambient or cooled rolls help achieve the perfect yarn quality for a range of materials and applications when it comes to heat treatment for filament fibre applications. Retech godet rolls have revolutionized synthetic fibre processing by providing unique designs that allow for greater control over temperature, fibre treatment and sustainability. In addition to its innovative designs, Retech also focuses on energy efficiency when it comes to motors and heating equipment. This means all Retech products use less energy than traditional systems—making them more cost effective over time while achieving excellent results.

Retech’s heated godet rolls are designed with two challenging requirements in mind: applying exactly the correct temperature for the material being produced; and maintaining this level continuously throughout the process. To do this, their designs incorporate energy saving technology, using single-zone or multi-zone heating via induction, infrared or resistance. This ensures accuracy and precision when it comes to surface temperature profiles - guaranteeing consistent yarn quality every time. Retech also offers unbeatable value when it comes to cost savings – thanks to its low maintenance requirements meaning less downtime, lifetime bearings meaning no additional lubrication required. As well as its IoT ready monitoring feature which protects against potential damage due to excess temperatures or other issues. This allows producers to produce higher yields at lower costs without risking product integrity or safety issues down the line.

IoTs in a modern heated godet: How to achieve sustainable heated godets?

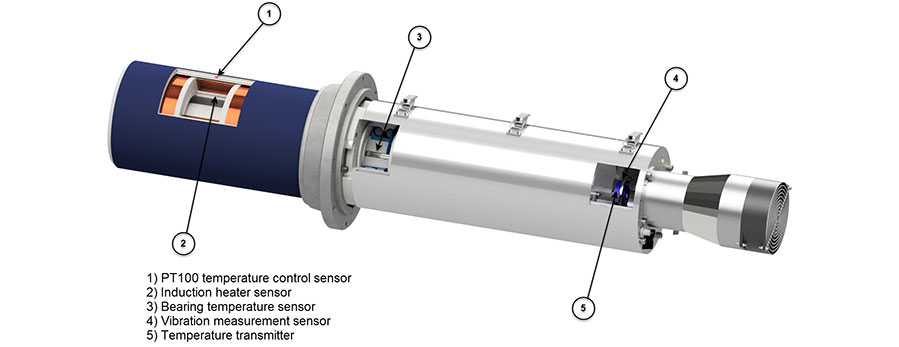

In addition to the energy-saving motors and energy-optimised heaters already mentioned, a very important part of the Retech godet concept is the long service life and the associated permanent availability, thus reducing machine downtimes and the production of rejects. If a godet fails, there is immediately a great loss, inconvenience and disruption to the production process. Therefore, Retech has equipped its godets with additional measuring elements in order to be able to react preventively to possible damage and subsequent failure. What options can Retech offer its customers and what are the advantages?

Thanks to the sophisticated, innovative and proven temperature measuring transmission system - UTR-6A, which measures the temperatures in the rotating godet and transmits the data to the temperature controller UCR-6 for processing without contact, it is possible to take further measurements, collect data and evaluate them. To protect the godet, the ongoing production and ultimately the sustainability of the entire process and the godet itself.

1. Induction temperature monitoring

By means of thermocouples, which are installed in the induction heater per heating zone, the temperature of the induction coil can be measured and monitored. If the temperature exceeds a value based on experience, the coil can be damaged and the service life reduced. If this temperature is exceeded, the system reacts with a warning and simultaneously switches on a cooling function. The operator now has the possibility to determine the cause of the increased temperature and to eliminate it.

2. Bearing temperature monitoring

If the bearing temperature exceeds a certain value, the bearing life decreases rapidly. The high-temperature grease decomposes and inevitably leads to bearing damage and godet failure. This leads to major expenses, downtimes and production losses. Therefore, it is essential to monitor the bearing temperature and to detect and delay an approaching bearing damage at an early stage until the bearings can be replaced as a precaution during planned maintenance work. Thanks to the possibility of installing, transmitting, displaying and evaluating additional temperature sensors in the temperature measurement transmission system below the bearing points, Retech offers comprehensive bearing failure prevention and monitoring, which represents a great added value for the operators.

3. Vibration monitoring

In addition to too high temperatures, vibrations can also damage a bearing and lead to bearing failures. If excessive vibrations can be detected and indicated, this would be a considerable added value for operators. This would allow an early and immediate reaction, and the cause of the vibrations could be determined and eliminated. This measurement has also been implemented in the temperature measurement transmission system. At the stator, the vibrations are measured, evaluated via the temperature controller and excessive vibrations are immediately communicated to the operator.

Of course, all this additional information and measurements are only really helpful if the operator then also takes measures and eliminates the causes. Depending on the process, the customer and his wishes, Retech offers different levels of measures. From a warning mode for a certain time to the shutdown of the godet, there are various options that are defined in detail with the customer. These new possibilities for extending the service life of heated godets are a milestone and a significant contribution to sustainability and reduction of the CO2 footprint.

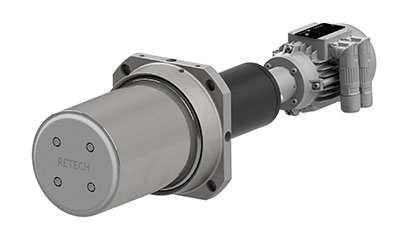

Today's demands on godets are not only faster, bigger, longer, which are required by the ever more advanced manufacturing processes and materials. "Slow" can also be a challenge. Certain processes require very slow speeds. The production of carbon fibres is just one of many examples in this field. Speeds of 0.1 - 10 m/min. can be a demanding task. To ensure that such slow speeds with a ratio of 1 : 100 can also be implemented in a stable manner, Retech has developed a new drive system. A central point is the elimination of the coupling that has been common in the industry up to now, which connected the bearing, gear and motor. With the godet generation presented at ITMA, the bearing, the gearbox and the motor are one unit. Depending on the requirements for speed, torque and gearbox angular, a modular system is available, which can be assembled according to the customer's needs. A highly interesting new product line that Retech can present.

Retech’s godets represent a unique design that enables customers to drive the draw roll allowing for very low speed applications of only a few meters per minutes or even per hour. This helps ensure top performance regardless of how slowly the process needs to run.

As a highlight, Retech shows the making of the blue thread. See live how this happens. By means of a demonstration object, the mentioned news and products can be seen live in action. All IoTs - vibration measurements, bearing temperature display, induction temperature measurement - will be shown. Also the new drive system for slow-running godets. And as a highlight, the innovative creation of the blue thread. For this, Retech will show a modular drawing system, which underlines the competence as a special solution provider for R&D facilities, universities and speciality manufacturers.

In addition to the 3 highlights mentioned above, Retech will also be presenting other innovative products from its range: the yarn tension sensors that have proved quality for years, the proved air-bearing separator rolls ..... true to the motto engineered and produced in Switzerland, Retech welcomes visitors to its stand B108 in Hall 1 at the ITMA in Milan!