#Spinning

A proper tool for the competitive DTY market

SSM GIUDICI FT machines (Fig. 1) have a very good reputation in the polyamide DTY (Drawn Textured Yarn) sector. Thanks to an optimized component surface and a unique yarn path design, they are the first choice of many polyamide producers focusing on producing the highest yarn quality. These features have now been unlocked for polyester DTY producers as well. SSM launched the new shaft texturing machine TG30-PES – the evolution of a proven machine concept.

The mass market is very cost competitive, so in this case the investment cost for a new machine is of great significance. The shaft machine concept offers advantages over the single-position machine concept, as such a design allows lower costs per spindle.

The H-profile shaped machine TG30-PES, allowing a twist stopper free yarn path, is a real advantage when processing fine- or microfiber DTY yarns. This doesn’t only apply to polyamide – it is also true for all other materials found in DTY, such as polyester, polypropylene, PBT or PTT. Historically, polyester texturing was performed using “V type” machine profiles, with the drawbacks of lower process efficiency, limitation in the minimum yarn count and higher maintenance costs.

Key factors for optimal yarn quality

Many factors influence the yarn quality. These include applying the twist in a concentrated process zone (heater, cooling and spindle), eliminating sharp angles in the yarn path, reducing the yarn path length, and eliminating the possible failures due to faulty twist stoppers, damaged bearings or broken ceramic. A short yarn path is a real benefit in terms of achieving maximum production speed. The yarn starts to vibrate at a certain velocity in a phenomenon known as “surging speed.” This affects both the process stability and the improvement of the yarn quality.

Another advantage of the ergonomic shaft texturing machine TG30-PES is that it features the proven electronic traverse guide system – in contrast to previous machine generations that had a traverse guide driven by a mechanical cam system. The cam gears of one deck were driven by a single motor.

Other features, like bobbin’s tapering or traverse variation, were performed by mechanical devices and limited in their range. Anti-patterning was done by simply varying the traverse guide velocity based on the principle of random winding. Although common for DTY machines, such anti patterning systems were not able to fully eliminate pattern zones, especially when processing fine yarn counts where the diameter of the package increases relatively slowly.

Benefits of the electronic traverse system

As SSM invented the electronic traverse system, it goes without saying that the system is also used on SSM shaft texturing machines, with the following benefits:

• Maintenance-free operation, no oiling/greasing required

• Elimination of possible oil/grease stains on the packages and therefore on the yarn

• Use of step-precision winding algorithm DIGICONE to produce pattern-free packages, with optimal unwinding performance

• Full flexibility in terms of bobbin’s shape, tapering, bulging compensation, etc.

• Marking A/B/C quality packages with a “belly band” winding specific to the bobbin’s quality – for fast and error-free sorting of produced packages

The TG30-PES machine is supplied with an integrated online tension and quality monitoring system GQS for package grading (A/B/C quality). It is operated via the same touchscreen terminal as the machine, which differentiates it from other standalone monitoring solutions.

Furthermore, a heated godet is available on the new shaft machine TG30-PES (Fig. 2). Heat-setting the DTY yarn to achieve the required elasticity is state-of-the-art in the production of polyester DTY yarns, but to use a heated godet to do so is a unique feature of SSM texturing machines. Unlike the conventional tube heaters used by competitors, heated godets bring the advantages of easier maintenance and superior ergonomics.

Designed and made in Italy

SSM produces its machines and systems in Italy, with most of the components sourced locally. Every machine is assembled and tested in the SSM factory in Northern Italy. Well-trained employees ensure trouble-free installation and commissioning at the customer’s site and provide a smooth and successful start-up.

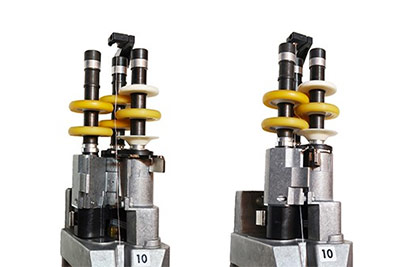

Open-close spindle concept

Every SSM false-twist texturing machine is equipped with open-close type spindles, enabling easy threading even with very fine and delicate yarns. This prevents mis-threading and damage to the friction discs, which can occur when inserting the yarn with a comb, especially when using polyurethane disc types (Fig. 3).

SSM is confident in the advantages of the “H type” machine profile as it results in higher process efficiency, lower yarn count options and reduced maintenance costs.

With the TG30-PES, SSM is offering texturizers the perfect tool to stay competitive in the false-twist texturing sector for medium-size to large bulk production of commodity yarns.