#Software

ECOmmerce research project completed

For two years, Avalution and Assyst conducted research together with the DITF Denkendorf in the ECOmmerce project, which was funded by the Deutsche Bundesstiftung Umwelt. As part of the research project, a technological solution was developed to help significantly reduce the number of returns in online retail.

Choosing the right product and creating awareness

Two challenges had to be combined into one solution within the project: How can a customer see on the screen at home whether they like and fit an item of clothing before they have physically tried it on, and at the same time how can they be made aware of the impact their online shopping behavior has on the environment while they are still in the ordering process? "It's a matter of both helping customers choose the right garment and making them aware that every product they send back is detrimental to the environment," explains project manager Dominik Michel, Avalution.

Bringing together expertise

As a fit expert, Avalution accesses the world's largest database of human body scans and can thus create a customizable avatar based on statistically accurate values with just a few personal details. Sister company Assyst is the German market leader when it comes to 3D clothing simulation. "The technological know-how of the two companies was the basis for the virtual fitting room, which has already been tested and is ready for use," says Dominik Michel.

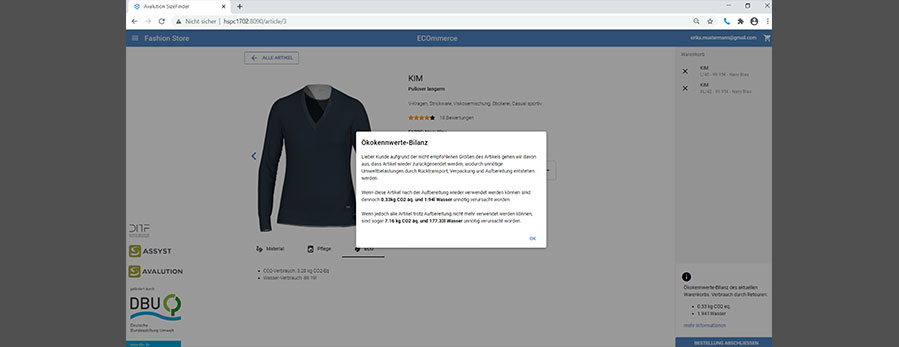

"The DITF worked on the eco-balancing package and developed an environmental sustainability assessment of the ordering processes for it. In the second half of the project, we developed a platform with real data from a large fashion company in which we brought the technologies together in a demonstrator-like manner, thus testing the project's findings in practice." In particular, this provides an eCommerce demonstrator that shows a new approach to reducing returns through fit visualization and ecological transparency and sustainability assessment.

Result achieved that can be built upon

Within the research project, the necessary technologies, infrastructures and processes were defined and the conditions for a fully digital sales process were created, which simultaneously makes the precise, ecological balance of a purchase transparent and determines the physically correct fit. The project started in the summer of 2018, with the Corona pandemic bringing home to the apparel industry the need for a faster digital process chain. "For our project, it has to be said that the last few months have given our results even more weight – now it is exciting to see what further use can now be made of the results," says Dominik Michel.