#Software

Lectra disrupts the automotive market

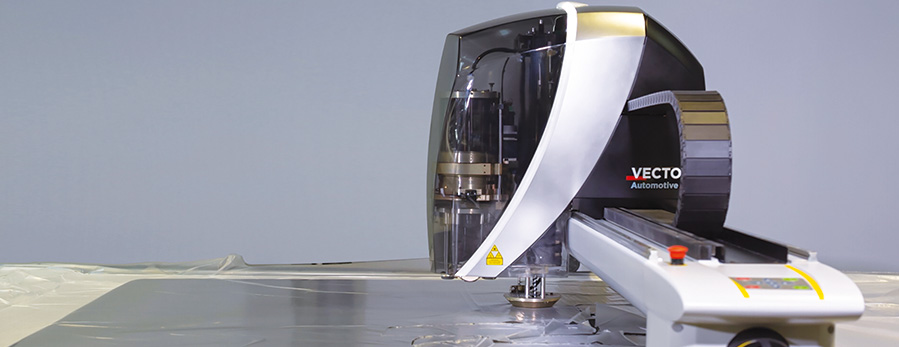

Extreme cutting precision of Vector® Automotive iP6 and iP9 provides tremendous material savings for automotive suppliers

Lectra’s R&D teams devoted three years to developing the technology required for zero-buffer cutting. Improvements in hardware components, an updated equipment pilot with a powerful new algorithm, and a specially designed blade will enable automotive suppliers to achieve hundreds of thousands of dollars in material savings annually as compared to other solutions available on the market.

Lectra developed the Vector Automotive iP series in direct response to the cost challenges faced by its automotive customers. Pressure from car manufacturers as well as rising manufacturing costs are driving automotive suppliers to constantly search for ways to cut costs. Material consumption is a particular area of concern, as this is the most significant expense in automotive car seat and interior manufacturing. With Vector Automotive iP6 and iP9, automotive suppliers will be able to achieve critical savings while minimizing the impact on their margins.

Constant, real-time control of the cutting equipment is integral to Vector Automotive iP6 and iP9’s ultraprecise cutting. Sensors on the cutting-head camera detect stress and instantly adapt cutting parameters. The new algorithm, an add-on to the equipment software pilot, manages common lines in real time for the greatest degree of accuracy possible while cutting parameters are continually adjusted to the blade’s dimensions.

In addition to substantially reducing material consumption, automotive customers will also benefit from lower consumable replacement costs and increased cutting time. Just as with materials, the new solutions enable an equivalent gain in paper and plastic films for each 1 mm reduction in buffer. Improvements in the bristle block, sharpening band and blade lifespans reduce maintenance time by half thereby drastically increasing machine availability.

Both solutions come with Vector Dashboard, a cloud-based application that allows users to monitor each equipment through daily key performance indicators. Thanks to centralized data, customers can identify key areas of improvement, focus on value-added activities and speed up the decision-making process.

“Lectra takes its commitment to being a trusted partner of the automotive industry very seriously. Our ongoing research investments are key in allowing us to develop sophisticated solutions that respond to our customers’ challenges, support their continuous improvement initiatives and help them improve their operational excellence. By enriching the Vector range with Vector Automotive iP6 and iP9, we provide our customers with the technology and expertise that will help them keep up with their customers’ needs,” explains Ce?line Choussy, Chief Marketing and Communications Officer, Lectra.