#Retail & Brands

M&S strikes landmark deal to buy biomethane gas certificates

The gas is then pumped into the national grid. M&S’ deal with Future Biogas funds the production and M&S benefits from the carbon reduction through the certification scheme.

It also provides significant revenues for farmers, giving break crops a commercial route to market not previously available.

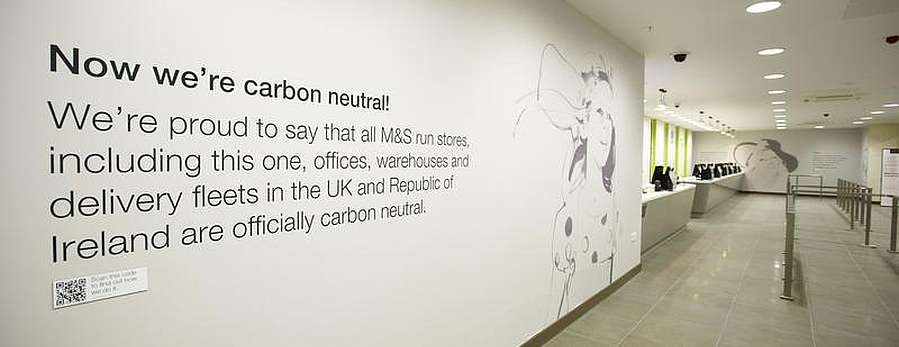

Since the inception of its “Plan A” programme, M&S has been a leader and innovator in supporting a renewable energy generation, including contracting directly with renewable generators under its award winning Price Guarantee Agreement structure.

Philipp Lukas, Future Biogas Managing Director said:“We are thrilled to be working with Marks & Spencer on this exciting and new venture. We look forward to supplying biomethane to M&S to help them deliver their market leading commitment to carbon reduction.”