#Research & Development

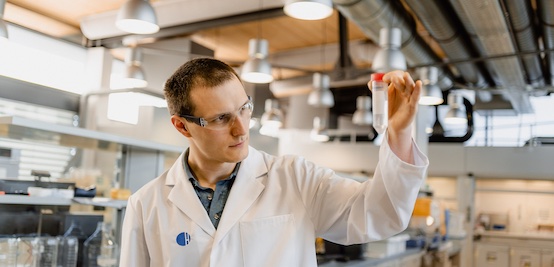

Well protected for sure

Protective clothing against infectious agents is used in many types of work: for example, work at sewage plants, waste disposal, animal care, disposal of hazardous waste from hospitals, etc. Workers are exposed to unknown infectious agents (microorganisms, parasites). The protective clothing should protect wearers from the mediums in which the microorganisms are contained, such as liquids, aerosols or solid dust particles.

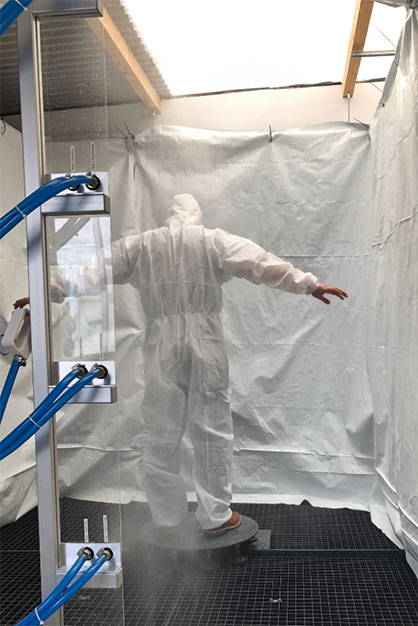

A chemical protective clothing is a personal protective equipment that protects the person wearing it from chemicals that surround him/her in a gaseous, liquid and / or solid state. They are classified into 6 types with different protection levels from gas-tight to restricted liquid-tight.

Hohenstein tests and certifies the following types:

- EN 14605: Protective clothing against liquid chemicals: Liquid-tight (type 3) or spray-tight (type 4) as well as partial protection types PB[3] and PB[4]

- EN 13982-1: Protective clothing against airborne solid particulates: Type 5

- EN 13034: Protective clothing against liquid chemicals: Type 6 and PB[6]

Detailed information is available at:

www.hohenstein.com/chemical-protection

www.hohenstein.com/infection-protection