#Recycling / Circular Economy

Introducing new swimwear fabric for circularity

The protection of our natural environment increasingly requires new concepts to meet the demands of consumption and sustainability in equal measure.

With the "Aqua Vision" project, sports brand manufacturer Decathlon has rethought the issue of recycling. The project focused on the development of a sportswear item that can be reused within the clothing sector, i.e., can be kept in circulation, and is also long-lasting.

"In practice, our goal was to be able to make a swimsuit from a swimsuit again," says Nathalie Bourdon, Offer Manager at Decathlon.

The challenge was to do this without using elastane in the production process. The filament with high polyurethane content ensures an excellent fit but causes problems in the recycling process. To master this challenge, Decathlon sought support from fiber manufacturer The LYCRA Company and textile machine specialist KARL MAYER GROUP.

Elasticity without elastane

The LYCRA Company provided the LYCRA® T400® EcoMade yarn. The stretch solution consists of 68% sustainable resources, with 50% of the content coming from recycled plastic and 18% from bio-based resources. Instead of using elastane, the LYCRA® T400® EcoMade fiber, in combination with a smart construction, provides the necessary stretch. LYCRA® T400® EcoMade fiber consists of two components, each of which shrink differently under heat during finishing. The result of this differential shrinkage is durable elasticity for a long-lasting fit. In addition, the yarn innovation offers another performance feature that is essential for swimwear: LYCRA® T400® EcoMade fiber is resistant to chlorine for over 500 hours, making it much more durable than conventional variants.

“At The LYCRA Company, sustainable innovation is at the heart of our vision, and we are proud to partner with Decathlon and KARL MAYER to produce a sustainably sourced, chlorine and wear durable swimsuit with no performance compromises which can be practically recycled at end of life”, said Arnaud Ruffin, The LYCRA Company’s Vice President for brands and retail.

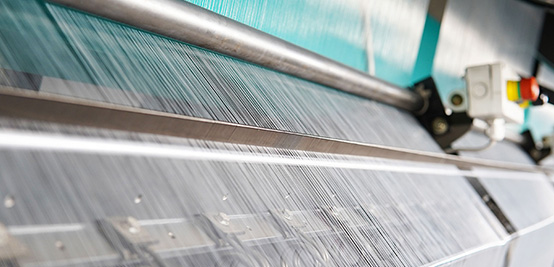

Processing into high-quality warp knitted fabrics

When processed into a smooth warp knit, LYCRA® T400® EcoMade fiber can fully realize its performance potentials. A two-bar warp knitting machine in gauge E 32 from KARL MAYER was used to produce the textile for the sustainable swimsuit. The renowned textile machinery manufacturer also provided support in the form of its know-how on a technical level.

"We tested whether the sustainable yarn behaves differently during processing than conventional variants. The tests were consistently positive. There were no losses in quality or efficiency," explains Michael Kieren from the New Business Development team at the KARL MAYER GROUP.

Sample presentation at ITMA 2023

Decathlon produced a swimsuit from a new fabric having supple elastic properties which can be recycled back into yarns for new apparel through the stages of collection, shredding, melting, pellet production and spinning. An example, recycled from a swimwear after its first cycle of use, will be presented by the KARL MAYER Group at ITMA, from June 8 to 14, 2023, in Fiera Milano on its stand in Hall 4 B119. The exhibition under the motto "Rethink. Reduce. Reuse - Close the loop" shows how waste and resources can be saved by consistently recycling materials. Recycling within the textile sector also ensures independence from other sources of raw materials for reprocessing.

However, in textile-to-textile recycling, coloration must be taken into account as early as the design stage, says Michael Kieren. Light colours are generally easier to recycle. To compensate for colour differences, the fabric becomes darker with each recycling process, he said.