#Recycling / Circular Economy

Nanollose creates the world’s first wearable fashion garment made from liquid waste

The sweater is the first of its kind and marks a breakthrough for an industry that is urgently seeking sustainable alternatives to clothing made from traditional rayon and cotton, both of which cause significant environmental issues.

Nanollose Executive Chairman Wayne Best said; “We have successfully taken waste and created clothing, and we have done it following industrial protocol. Our fibre was spun into yarn and made into fabric, then manufactured into this garment using existing industrial equipment. It validates our entire process.”

150 million trees are cut down each year, then chipped and treated with hazardous chemicals to extract the raw material used to make Viscose Rayon fibres for clothing. By contrast, Nanollose’s Nullarbor fibre is made without harming a single tree.

“We didn’t have to cut down any trees to create this sweater, and we have now demonstrated that our Tree-Free Rayon fibre can be used in the same way as other commonly-used fibres to make clothing and textiles, without the hefty environmental footprint.” Mr Best said

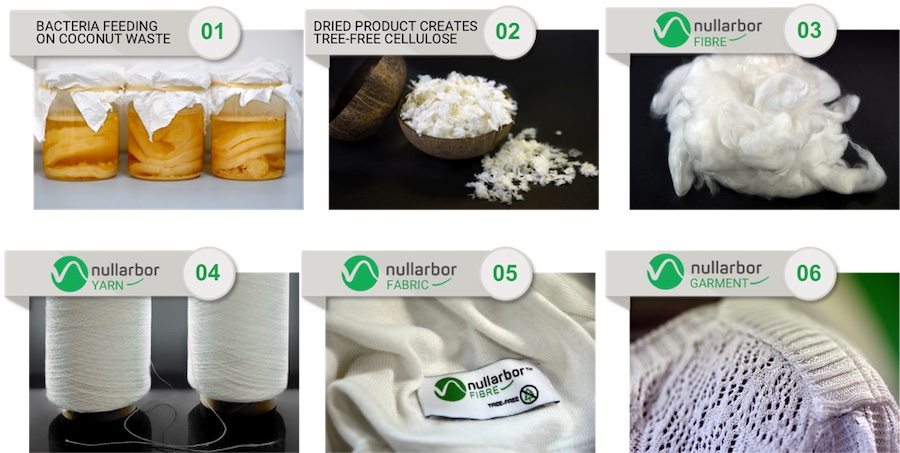

Nanollose’s innovative biomaterial technology process begins in a facility where microbes naturally ferment liquid waste products from food industries into cellulose, a cotton-like a raw material that then is transformed into their Nullarbor fibre.

Their process to produce cellulose requires very little land, water or energy and a production cycle is just 18 days, compared to the eight months seen in the cotton industry.

“We believe that we are the only company producing Tree-Free Rayon fibres from waste, and we have now reached a point where our technology is moving out of the laboratory and into the factory. Once we achieve this increased scale, manufactures will have an alternative eco-friendly option available to them.” said Mr Best.

As more and more headlines revealing the environmental impact of the textile industry emerge, there is an increasing urgency among consumers, brands, retailers and manufacturers to seek and cultivate alternative fibre resources.

“Progressive brands and companies are starting to facilitate this new shift by involving themselves deeper in the supply chain and searching for feasible, sustainable long-term alternatives. This is evident in the increasing number of enquires we have received over the past six months.” Mr Best said.

This urgency for cleaner alternatives saw retail juggernaut H&M release a sustainability report in April 2017, highlighting their commitment to use 100% sustainably sourced materials by 2030. Similarly, Zara joined the movement with the launch of their new sustainable line ‘Join Life’ modelled by Sasha Pivovrova.

To ensure Nanollose can supply future partners with commercial qualities of fibre, the company is developing a supply chain within an ecosystem around waste from the Indonesian coconut industry (along with waste streams from other industries), and aims to significantly increase fibre production over the next 3-6 months.

“We are a technology company, that has also become a steward in facilitating a new raw material supply chain. The goal is to work with key partners who will simply take waste (instead of trees), produce our Nularbor fibre, and seamlessly integrate them into their clothing supply chain with no retrofitting to existing machinery or processes required”