#Recycling / Circular Economy

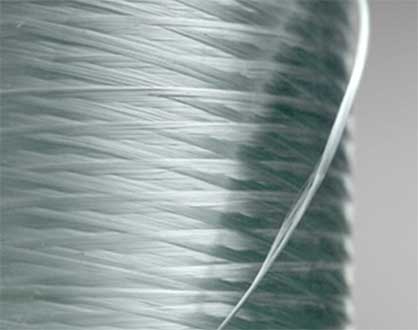

DSM and SABIC combine efforts to create recycled-based Dyneema®

By working together with members of CirculariTeam®, DSM will produce recycled-based Dyneema® made using SABIC’s certified circular ethylene as a pilot project in both a sailing rope and a pelagic trawl net application. The circular ethylene, from SABIC’s TRUCIRCLE™ portfolio, uses mixed plastic waste as feedstock (mass balance approach), which not only contributes to preventing valuable plastic from becoming waste and the avoidance of carbon emissions compared to incineration, but it will also help preserve fossil resources. These pilots are an important early-stage milestone in the journey toward making fully circular Dyneema® from HMPE post-production and post-consumer waste.

Jan-Lodewijk Lindemulder, President DSM Protective Materials: “This achievement is a key milestone on the journey toward our goal of delivering a fully circular Dyneema®. By working with partners from across the value chain, we are able to significantly reduce the environmental impact of the world’s strongest fiber – and we will continue to explore ways of reducing and eliminating waste across the entire product lifecycle.”

Mark Vester, Circular Economy Leader at SABIC: “At SABIC, we firmly believe that only through collaboration and innovation can we drive forward and develop solutions that meet the needs of all stakeholders. This is another important step closer to closing the loop on Dyneema®. Moving forward, through our TRUCIRCLE™ solutions and beyond, we will continue to make every effort to deliver a more sustainable value chain and economy.”

Jon Mitchell, Managing Director at Marlow Ropes: “We’re proud to be one of the first manufacturers to integrate recycled-based Dyneema® within our products and demonstrate the material’s feasibility. By collaborating with materials science pioneers such as DSM and SABIC, we are able to create products that not only deliver superlative functional performance but also have a lower environmental impact. Our products are trialed and tested by professional offshore sailing teams including 11th Hour Racing Team, a proud partner of ours at Marlow, with whom we share a progressive approach to seeking sustainable solutions: no more business as usual."

Klaus Walther, Managing Director at Gleistein: “Warm congratulations to DSM and SABIC for pushing the boundaries of science to deliver a truly unique product. We’re proud that our ropes can be produced from what once was typical household plastic waste. This is an important stepping stone towards becoming circular. It will enable our customer Maritiem BV to further develop high-tech fishing gear whilst contributing to the circular economy. Not to forget Cornelis Vrolijk Fishing Company, who again illustrate their commitment to Corporate Social Responsibility by introducing this concept in fishery.”