#Nonwovens / Technical Textiles

TRÜTZSCHLER Nonwovens integrates BASTIAN Winder Technology

"The technologically outstanding products of Bastian supplement our product programme so that we can now offer the customer a perfect solution down to the winder. The customer no longer has to worry about interfaces, but will receive a perfectly aligned solution," says Marc Wolpers, managing director of Trützschler Nonwovens.

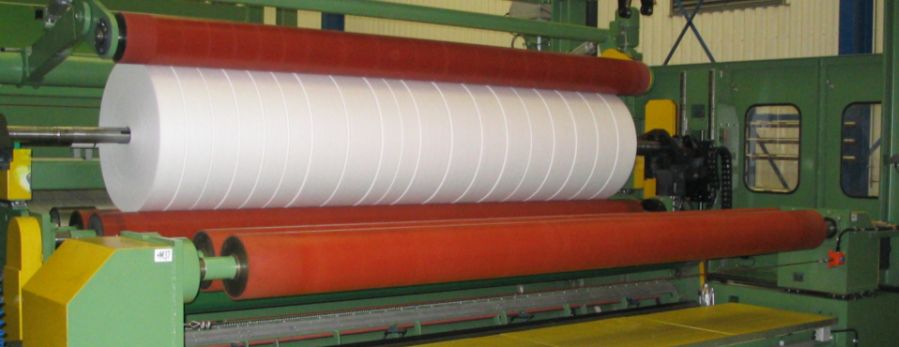

Under the name of BASTIAN, TRÜTZSCHLER NONWOVENS will in future offer winders for nonwovens, film, paper and composites.

Use of the perfect winder and selection of the correct slitting system ensure the quality and productivity of the plant and therefore success of the final product.

Based on many years of experience and industry-specific know-how, the BASTIAN experts can now evaluate exactly what is technologically possible end economically convincing in combination with the expertise of TRÜTZSCHLER NONWOVENS.

"We are happy that the experienced BASTIAN employees continue to be available to our customers," continues Wolpers.

TRÜTZSCHLER NONWOVENS offers leading technologies for the producers of nonwovens and technical textiles around the world.