#Nonwovens / Technical Textiles

Innovating for New Mobility: Autoneum expands global research and development capacities

Innovation is and always has been an integral part of Autoneum’s corporate strategy and thus a key factor for business success. The Company’s innovation activities are also an important aspect of its vision: to be the global leader for innovative and sustainable solutions bringing comfort to every vehicle. Against the backdrop of the rapidly advancing electrification of mobility and Autoneum’s strategic focus on further expanding its presence in the Asian growth markets, the expansion activities of the company-wide innovation network this year concentrated on two key areas in particular: New Mobility and presence in China.

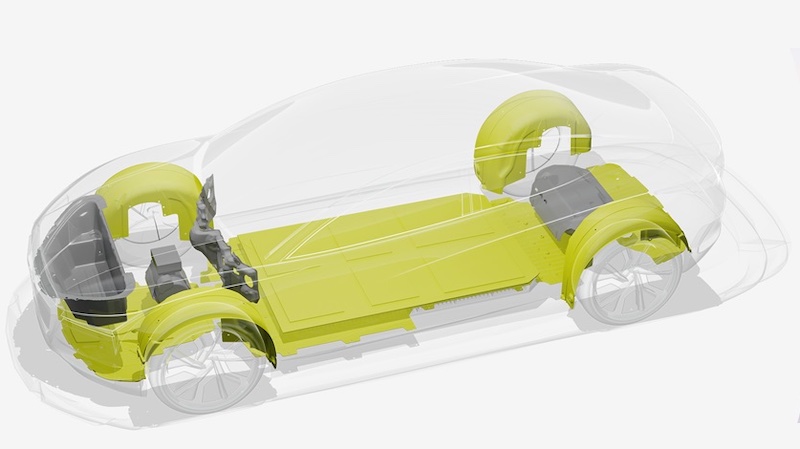

Responding to the increasing demand for new components for electric vehicles, Autoneum has formed a specialized team dedicated exclusively to New Mobility to further strengthen its position in this growing market segment. The New Mobility team was established in fall 2023 and has been completed over the past twelve months with members from different departments. It unites a broad set of skills from various fields of expertise such as product innovation, product development and industrialization, sales and business development. The team places a particular focus on accelerating the development and time to market of new products and technologies specifically for the fast-evolving battery systems and architectures of electric vehicles. It also acts as a catalyst for innovation projects and strategic partnerships. The New Mobility experts work in close collaboration with the various departments across the organization and are based at Autoneum’s Swiss headquarters in Winterthur, at the German locations in Gundernhausen and Munich and in Shanghai, China.

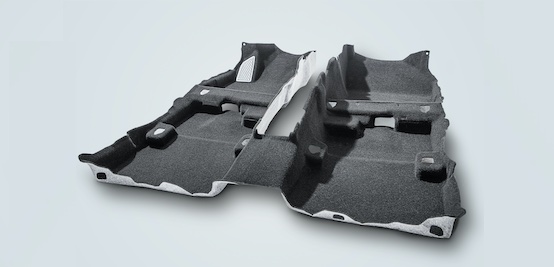

Shanghai is also the location of Autoneum’s third R&T Center worldwide, which was opened in China this summer to enhance the Company’s competitiveness in Asia and cater to the development and innovation needs in this key strategic market. The new center aims to intensify and accelerate the development and production of innovative components and materials, especially regarding e-mobility. The establishment of an R&T team in China allows Autoneum to develop products in a timely manner to respond to the dynamic market conditions and the rapidly evolving requirements of Chinese vehicle manufactures. In terms of material development, the center will support the wider organization in the further development of sustainable materials, especially polyester. In addition, it will promote the introduction of Autoneum’s environmentally friendly products such as the Company’s monomaterial carpet systems featuring Autoneum’s innovative and latex-free alternative backcoating (ABC) process to the Chinese market. Moreover, the R&T Center in Shanghai will also serve as a valuable point of contact with the 14 production facilities of the Jiangsu Huanyu Group, whose acquisition of a majority stake of 70 percent by Autoneum was recently announced and is expected to be closed in March 2025 (see media release of November 19, 2024). While the plants in China will benefit from the local R&T team’s expertise in the company’s technologies, the existing broad customer base of Jiangsu Huanyu Group will support Autoneum in better understanding and serving the innovation needs of Chinese vehicle manufacturers.

The new R&T Center in Shanghai complements the primary R&T Center in Winterthur, Switzerland, which supports the global network with its expertise and a vast array of services in the areas of pre-development as well as acoustic and thermal benchmarking, simulation and testing, and the center in Bocholt, Germany. The latter was integrated into Autoneum’s innovation network following the acquisition of Borgers Automotive last year and has since established itself as the Company’s competence center for trunk and trim components. Including the new center in China, a total of approximately eighty R&T employees – including engineers, chemists, physicists and product designers – are continuously working on new ideas aimed at the next technological breakthrough in acoustic and thermal management and shielding technologies.

Further details on Autoneum’s global research and development activities and the key drives of the Company’s innovation activities can be found here:

https://www.autoneum.com/innovation/research-and-development/