#Nonwovens / Technical Textiles

Autoneum presented corporate strategy and medium-term targets with planned revenue growth up to CHF 3 billion

In his introductory speech, CEO Eelco Spoelder addressed the current challenges and developments within the automotive industry and presented the Company’s mission statement, which formed the foundation of Autoneum’s “Level Up” strategy. The strategy was built on six key pillars: shaping a future-fit product portfolio, innovating to create customer value, accelerating global growth, fostering a people-centric culture, being the sustainability benchmark, and boosting cost competitiveness. Spoelder explained how various strategic initiatives aimed to increase order intake and profitability.

Pascaline Brégeon, Head of Strategy and Sustainability, provided an overview of the current sustainability regulations and highlighted how Autoneum was transforming challenges into opportunities to further strengthen its global market leadership.

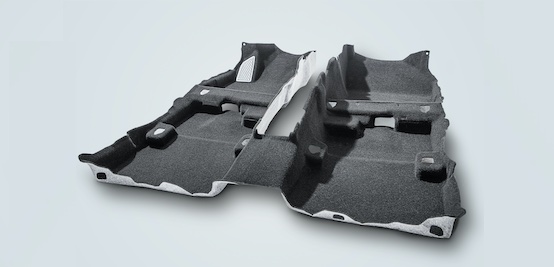

Philippe Godano, Head of Core Technologies Research & Technology, discussed how technological trends in the automotive industry and evolving customer needs influenced Autoneum’s innovation processes. He showcased the development of new technologies and products, which further enhanced the Company's already balanced and future-ready product portfolio.

Finally, CFO Bernhard Wiehl presented the revised medium-term targets. Supported by a comprehensive package of strategic initiatives and a focused increase in market share with both existing and new customers, Autoneum planned to reach revenue growth up to CHF 3 billion in the medium term. With the expected revenue growth*, a consistently implemented strategy, enhanced operational excellence, the promotion of innovation, and sustainable processes, Autoneum anticipated an EBIT margin of 6% to 8% over the business cycle. The Company also aimed for solid free cash flow of at least 5% of revenue and a net debt to EBITDA ratio of less than 1.5x.

In line with its commitment to sustainability, two of the most important environmental, social, and governance (ESG) goals** were integrated into the medium-term targets: a 20% reduction in CO2 emissions (Scope 1 and 2) and a 40% reduction in non-hazardous waste by 2027, compared to 2019 levels.

Autoneum also reaffirmed its long-standing dividend policy of paying a dividend of at least 30% of the profit attributable to Autoneum shareholders.

*Based on the S&P market forecast as of September 18, 2024

**As part of the comprehensive sustainability goals communicated in the CR Report 2023.