#Nonwovens / Technical Textiles

BMW M Visionary Materials Seat wins 2024 Altair Enlighten Award in the Sustainable Process category

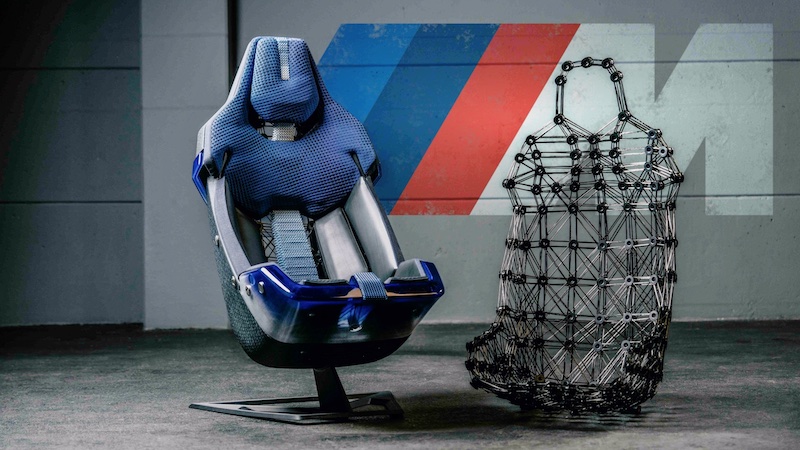

The BMW Group received the award for the BMW M Visionary Materials Seat on the grounds that the research project is a precursor of future product development: Standout achievements were the sustainable seat design and the focus on the entire product lifecycle, making it one of the most innovative and visionary sustainable developments in the global automotive sector.

In addition to BMW M GmbH as the project owner, BMW Group Designworks was responsible for the design, color and material concept of the seat in collaboration with the BMW design team. The project was realized in close cooperation with several partners: Automotive Management Consulting GmbH, Bcomp Ltd, Gradel Lightweight Sàrl and Lasso Ingenieurgesellschaft mbH.

Key themes: design for circularity, lightweight construction and attractive product

As a platform for research on the development of future materials, the award-winning seat focuses on the following key themes:

First, driving the use of plant-based materials and, as part of design for circularity, raising the share of secondary raw materials and increasing recyclability at the end of the lifecycle.

In addition, the team aimed to develop an attractive product in terms of its appearance, quality, lightweight construction and functionality. The minimalist design leaves the lightweight seat structure visible, highlighting its status as a core component. Intensive lifecycle assessments (LCA) complemented the design at each stage of development.

Falco Hollmann, Innovation Manager Lightweight Design & Sustainability at BMW M GmbH, accepted the award: “We are showing today what will be possible tomorrow with existing technologies and materials in order to take our efforts to reduce emissions and conserve resources to the next level. This is about more than just substituting materials; it is above all about designing for circularity.”

Use of natural materials

The core premise of the project was to make the leap to the future while working within today’s framework. The evaluation of available material classes with a high SQR (secondary raw material quota) showed that natural materials are the ideal complement. For example, the seat features natural fibers, fiber composites, leather alternatives and algae-based polymers.

Carbon footprint reduced by 90 percent

The seat’s CO2e footprint is 90 percent lower than a BMW M carbon bucket seat made today, thanks to the use of ultra-light, robotically-wound fiber composite seat support structures and materials of natural origin as well as the high recycling rate. In addition, lower module complexity and the use of materials grouped by type make it easier to recycle the seat at the end of its lifecycle. The additive manufacturing processes used are also groundbreaking: A new technology made it possible to completely eliminate support structures, chemical post-treatment and finishing from the M BMW Visionary Materials Seat. Other priorities included a flat value creation chain and a minimum of finishing steps to save energy and conserve resources.

Lessons learned for future processes

“One of our biggest lessons was the balancing, in other words, how to model our process chain to generate missing primary data,” explains Roberto Rossetti, Head of Development Total Vehicle-Lifecycle at the BMW Group. “The data obtained provides new insights, both in terms of today’s negative contributing factors and the design of tomorrow’s processes. This experience provides a solid foundation for continuously improving sustainability and developing innovative solutions for forward-thinking mobility.”