#Nonwoven machines

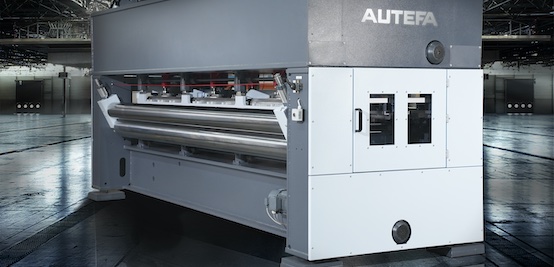

AUTEFA Solutions excels in the premier league of needling

Current projects for papermaking felts productions lines

The production of papermaking felts is one of the most complex processes in the nonwovens industry. It combines the highest quality standards with unusual requirements for fabric width and desired basis weight. Papermaking felts are used in the drying stage of the papermaking process and play a crucial role in determining the surface quality of the final product. Another feature is that they can be produced in almost endless lengths, which is essential to avoid marking at the joints. The design of papermaking felt lines is therefore also a major challenge for textile machinery manufacturers.

André Imhof, CEO of AUTEFA Solutions Austria GmbH, explains: "The double closed-loop system, which offers the best CV-value increases speed and improves productivity. With Service 4.0, we offer comprehensive support through service contracts, 24/7 remote access and technical assistance. We are committed to achieving superior surface quality and offer customized needle board patterns using the i- Point needle simulation tool to improve the capacity and quality of needlepunched fabrics.

Our recipe sequence control ensures that all machine adjustments are made in the right order and at the right time during product changeovers. This enables our customers to reduce production waste during product changeovers by up to 70%. This not only contributes to sustainability, but also significantly increases profitability. Our customers are so convinced that they have entrusted us in 2023, with the production of a total of two complete papermaking felting lines, including finishing needle machines, for locations in Europe and Asia.

We are also pleased to be able to equip an existing facility in Europe with a new Stylus NL 19 finish needle loom. The manufacturers' goal with these investments is to operate the most modern, efficient, and sustainable papermaking felt production facilities in the industry - goals that we at AUTEFA Solutions are fully committed to supporting.

From fiber to papermaking felt

In needle punching lines for papermakers' felts, AUTEFA's customers rely on the company's expertise from fiber preparation to finish needle punching to meet their defined requirements in the most effective way. After gentle fiber preparation, the Masterfelt carding machines come into play, guaranteeing the highest fiber blending effects without stressing individual fibers. The downstream combination of the Topliner crosslapper with the patented Closed-Loop System and WebMax web profile control system prevents excessive fabric weight in the edge areas, known as the "smile effect", and ensures excellent fabric uniformity. Several measuring points are distributed throughout the line for process monitoring.

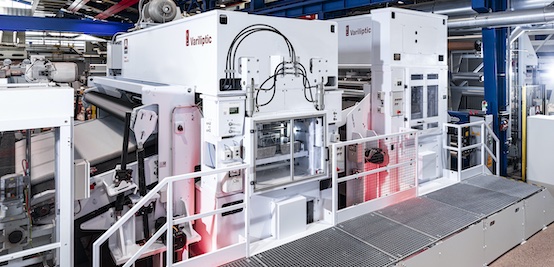

This is followed by the first bonding stage with the NL16 Stylus Variliptic pre-needle loom. Thanks to the patented Variliptic drive modules, the NL16 Variliptic offers an improved fabric surface, higher production speeds, less distortion, less shrinkage, and better uniformity. Finally, the NL19 Finishing Needle Loom Stylus is used to achieve the desired surface quality. Together they form the core of the high-end production lines, which are individually tailored to customer requirements in terms of working width, number and arrangement of needle zones, needle patterns, stroke frequency, feed tables and fabric tensioning systems. Integrated, fully automatic fabric production according to recipe, with precise stops for bonding and fabric tension control, represents the state of the art.

The production of papermaking felts requires the highest precision, especially in the needling process over the entire working width. AUTEFA Solutions achieves this with ingeniously designed rigid steel frames that allow minimal vibration even at working widths of up to 17 meters. The continuous stroke frequency of 1,200 rpm results in a surface quality that meets the specified requirements.

As a turnkey supplier of nonwoven lines and machines, AUTEFA Solutions offers needle punching lines, aerodynamic web forming lines, hydroentanglement lines and thermal bonding lines. AUTEFA Solutions is a solution provider for complex tasks where attention to detail counts and combines the technologies of the well-known companies AUTEFA, Fehrer, F.O.R. and Strahm Hi-Tech.