#Nonwovens / Technical Textiles

BRENTA – Sympatex’s impressive impulse generator at A+A

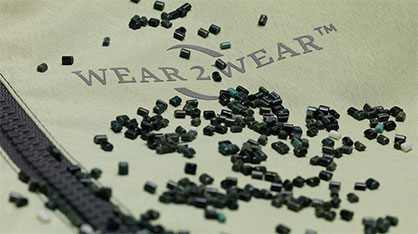

Sympatex will be presenting its Brenta product for the first time in Hall 5, Stand C14, at A+A, the leading trade fair for safety and health at work, in Düsseldorf. The focus of the 37th A+A is on sustainable occupational safety of the future. With its newly developed corporate workwear jacket, Sympatex is demonstrating that technology and sustainability can only set the pace in the industry if they work together. The 2-layer laminate is made of 100% polyester. This purity of type is regarded as the only efficient solution in terms of the valuable recycling of scarce raw materials and the urgently needed reduction of CO2 emissions, as well as the reduction of wa-ter consumption in the production of the laminate.

“A+A 2021 gives us the opportunity to present our consistently circular portfolio to a large number of customers. We can show that top performance and genuine sustainability are not mutually exclusive in modern functional clothing, says Stefan Prestel, Sales Manager Contract & Workwear.

“Brenta” is a particularly good example of this. The pleasant stretch of the material does wit-hout any elastane at all. This means that the laminate remains 100% recyclable, because it is unmixed, and therefore fulfils far more than the upcoming, stricter EU regulations,” adds Pres-tel.

Few membrane manufacturers are as relaxed about the latest EU initiatives as Sympatex. Be-cause what Sympatex has been promoting for 30 years is now becoming the norm: the circular economy model of the future. In the course of this, for example, the production and use of per-fluoroalkyl substances (PFAS) will be banned in future by the REACH restriction process, as these have long posed an unacceptable risk to the environment and to people. The Sympatex membrane is made of polyether ester, which is harmless to health, and is free of PTFE and PFC. This means that it already complies with future EU regulations.

“Whether it’s the EU’s general textile strategy, the corresponding legislative initiative (SPI) or detailed regulations for extended corporate responsibility (EPR) and the obligation to provide proof of product information (“green claims”), this year the EU has sent a framework on its way that will fundamentally change our industry like never before,” says Dr. Rüdiger Fox, CEO and Chief Environmental Activist at Sympatex. “The commitment to circularity, to transparency 4 regarding sustainability and the ban on fluorochemicals make it necessary to completely rethink our portfolio concepts of the past.

It is high time not only for our industry but also for public procurement to adapt to this. We are very glad that we started doing this years ago.”

The future of work has probably never been more exciting. Under the motto “People count”, A+A 2021 is dedicated to the trend themes of “Solutions for the future”, “Digitalisation”, “Sustainability”, “New working worlds” and “Pandemics”. A+A is thus the platform when it comes to presenting new products, solutions and ideas for a rapidly changing working world. Come to the Sympatex stand (Hall 5, Stand C14) and discover the entire product portfolio. All tickets can be purchased online via the Messe Düsseldorf website aplusa.de.