#INDEX 20

ANDRITZ at INDEX20

The broad ANDRITZ product portfolio covers state-of-the-art nonwovens and textile production technologies such as air-through bonding, needlepunch, spunlace, spunbond, wetlaid/WetlaceTM, converting, textile finishing, airlay, recycling, and natural fiber processing.

ANDRITZ LAROCHE, FRANCE, PART OF THE ANDRITZ GROUP

One highlight at INDEX will be the new member of the ANDRITZ Nonwoven division: ANDRITZ Laroche – a company that has been a very important partner for ANDRITZ in the field of fiber preparation for drylaid nonwovens for over 10 years. ANDRITZ Laroche is a leading supplier of fiber processing technologies such as opening, blending and dosing, airlay web forming, textile waste recycling, and decortication of bast fibers.

One focus of this product range is complete recycling lines for post-consumer and industrial textile waste to produce fibers for re-spinning and/or nonwoven end-uses. Customer awareness and regulations are pushing clothing brands to recycle their textile waste in their own products. Recycled fibers can also be used in the nonwovens industry for various applications, such as automotive, insulation, mattresses, and furniture felts.

TRENDS, INNOVATIONS AND HIGHLIGHTS

Sustainability is a serious responsibility for the entire industry and will continue to be so for the years and decades to come. ANDRITZ’s “We Care” sustainability program combines all ESG (Environment, Social, Governance) initiatives, goals and achievements under one roof. “We Care” takes a multi-dimensional, comprehensive, and practically oriented approach towards sustainability. For each of the focus topics, ANDRITZ has set itself ambitious goals aimed at making the business activities of ANDRITZ and its stakeholders more sustainable.

For many years now, ANDRITZ has offered different nonwoven processes, like spunlace, Wetlace and Wetlace CP, with one goal in mind: reduction and elimination of plastic components while maintaining the high quality of the desired product properties. The latest development in this field is the ANDRITZ neXline wetlace CP line. This is a fully engineered production line combining the benefits of wetlaid and drylaid technologies to produce a new generation of biodegradable wipes.

To serve customers even better and offer the best possible R&D and service, ANDRITZ has invested in and upgraded its technical center in Montbonnot, France, to a Wetlace CP line. It is the first nonwovens test center for wipes worldwide with integrated pulp formation. Customers can conduct trials and test all options for wipes together with our experts.

In response to the demand to save raw materials, ANDRITZ will be presenting its neXline spunlace for lightweight fabrics. Decreasing weight per square meter while maintaining high MD and CD tensile strength is the main challenge. ANDRITZ provides the well-known TT card web forming and the high-performance Jetlace hydroentanglement units, which can more than fulfill these demands. The spunlace roll goods can achieve weights of 25 gsm and even less for ultralight spunlace fabrics, and web uniformity is excellent.

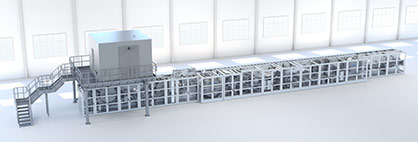

Moreover, ANDRITZ will also introduce its adult pants converting line, which offers top-class components and an innovative technology process. The growing market for adult incontinence products has resulted in a state-of-the-art process with highest quality standards, such as the development of ultrasonic side seam solutions with excellent results in terms of bond strength and system reliability. The machine speed no longer limits quality bonds. As a result, operations and size changes are faster and easier. The modern forming system for higher SAP (superabsorbent polymers) concentration and the turning and placing system guarantee maximum process stability and put customers’ adult pants at the top of the adult hygiene market.

Another highlight at INDEX will be the latest technology developments in the spunlaid sector. For instance, the patented nonwovens process called Spunjet is the in-line hydroentanglement of continuous filaments, creating a new generation of spunlaid nonwovens with unrivalled bulkiness and softness compared to standard spunbond fabrics. Spunjet offers customers the best properties ever achieved in existing and new nonwovens applications.

PROCESS AND PRODUCT OPTIMIZATION

ANDRITZ is also presenting the brand new ProWin technology for profile weight correction, which is used to optimize processes, provide a faster return on investment, and save raw materials in the needlepunch segment. This unit combines the well-known technologies ProWid and ProDyn, enabling even better performance. By uniting these processes, customers have an even more homogeneous web and can reduce the input of raw materials. ProWin minimizes the level of instantaneous acceleration as well as the maximum internal speeds. As a consequence, the same machine can run faster with less mechanical stress. ProWin can also be retrofitted to recent ProDyn installations.

In addition, ANDRITZ is active in the automotive sector. The latest generation of double velour needleloom SDV2+2 produces excellent nonwoven fabrics’ visual aspect with a good surface evenness. It also allows composite fabrics production (latex free mechanical consolidation), highly participating in the sustainability approach, becoming more and more a requirement from the automotive industry. This development is available in the advanced needlepunch technical center located at ANDRITZ Nonwoven facilities in Elbeuf, France, where needlepunch customers are welcome to conduct trials and develop new products.

Furthermore, with the Metris Remote Access Service (Metris RAS), for example, ANDRITZ uses an advanced solution to provide customers with guidance and remote support for their production lines from a distance. Metris RAS provides a set of tools for audio, video and, optionally, AR-supported communication between an engineer in the field and the experts in our back-offices to identify and resolve any issues quickly and smoothly, with fewer misunderstandings and no unnecessary, additional calls. Thanks to this tool, ANDRITZ has succeeded in assisting customers online with machine maintenance and start-ups in spite of lockdown and travel restrictions.

VISIT THE ANDRITZ BOOTH – PHYSICALLY AND DIGITALLY

A very special highlight for INDEX is the virtual booth called the “ANDRITZ Teleport”. Customers and business partners can enter this booth via the INDEX virtual platform and meet the ANDRITZ online sales and service team. They will have the opportunity there to talk directly to the team, discover state-of-the-art technologies, and obtain the latest marketing material and press information. A wide range of opportunities awaits our customers and business partners!

The entire ANDRITZ Nonwoven team is looking forward to welcoming customers to our booth (2114 and 2080) in person and also online in our virtual booth – the “ANDRITZ Teleport”.