#Nonwovens / Technical Textiles

Murata and Teijin Frontier jointly innovate fabric with antimicrobial performance

Establishment of a joint venture company to develop a plant-derived fabric that emits electricity, creating a better environment

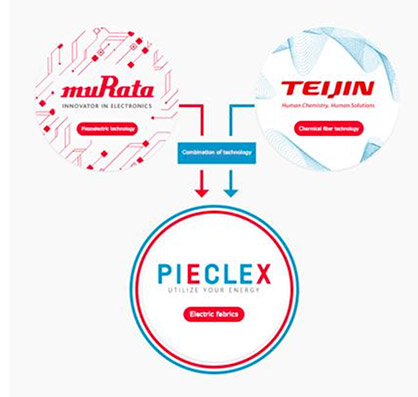

Also, Murata and Teijin Frontier jointly established PIECLEX Co., Ltd. (Head Office: Yasu City, Shiga Prefecture, President and Representative Director: Daiji Tamakura) on April 1, 2020 as a joint venture company for the purpose of research, development, manufacturing and sales of this fabric.

PIECLEX fabric realizes antimicrobial performance by converting motions such as human movement into electrical energy by combining Murata's piezoelectric technology cultivated through development and manufacture of electronic components with Teijin Frontier's fabrictechnology, which spans from yarns andmaterials to product manufacturing. PIECLEX also contribute to protecting the global environment as ituses plant-derived polylactic acid (PLA) as its raw material anddoes not applychemical agents and organic solvents.

PIECLEX is a carbon-neutral, earth-friendly fabric

PIECLEX uses PLA, which is produced by fermented starch extracted from plants to produce lactic acid then bonded. Since plants absorb carbon dioxide in the atmosphere and synthesize starch, PIECLEX does not increase the total amount of carbon dioxide that causes global warming.

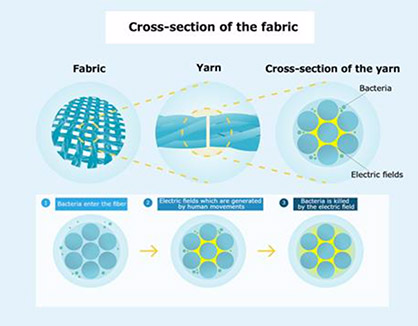

Utilizes piezoelectric technology to achieve antimicrobial and deodorant(*) functions without using of chemical agents

PIECLEX fabric generates electricity by using the expansion and contraction of the fabric produced by human movement or other motions. This enables antimicrobial and deodorant functions without using chemical agents or organic solvents, helping to reduce the environmental load.

(*) Antibacterial function which prevents odor generated by bacteria that decomposes sweat and sebum

Future development

(1) Going forward, PIECLEX Co., Ltd. will develop a wide range of applications of PIECLEX, from clothing products such as sportswear and innerwear to industrial products including filters and sanitary materials.

(2) Production and sales will start from fiscal 2020, with the goal of 10 billion yen in sales by fiscal 2025.

Murata’s Chairman of the Board and President Tsuneo Murata had the following to say about the joint venture:

"The fabric developed by the newly established PIECLEX Co., Ltd. makes use of Murata’s piezoelectric technology and knowledge cultivated through products such as SAW filters, resonators, and sensors. To the present, Murata has contributed mainly in the field of electronic equipment, and I am very happy that this combination with Teijin Frontier's fabric technology will let us challenge the creation of new value in the field of fabrics. This joint venture will make the most of both companies' strengths and contribute to the creation of prosperous lifestyles through electrical fabrics."

Teijin Frontier's President Chief Executive Officer Shinji Nikko said about the joint venture:

"The piezoelectric fabric developed by PIECLEX Co., Ltd. realizes antimicrobial performance without using chemical agents, etc. It also contributes to environmental load reduction as it applies plant-derived raw materials. PIECLEX integrates Murata and Teijin Frontier’s cutting-edge technologies, and I believe this innovative fabric will be essential for sustainable future lifestyle. By providing fabric that have never existed before, we will contribute to realize bountiful lifestyles and beautiful environment."