#Nonwovens / Technical Textiles

Protective masks for Europe

With protective masks – including those used in operating rooms – this quality is provided above all by virus-absorbing nonwovens. And these will be manufactured by the new venture ‘FleeceforEurope’ in Germany using an Oerlikon Nonwoven meltblown system.But all masks are not created equally. For this reason, protection against infections such as corona-virus can only be guaranteed with the right quality. On the one hand, this relates to how the masks are made. On the other hand, it is above all – as is so often the case – about what’s inside. Because the nonwoven used in protection class FFP1 through FFP3 respiratory masks plays a decisive role.

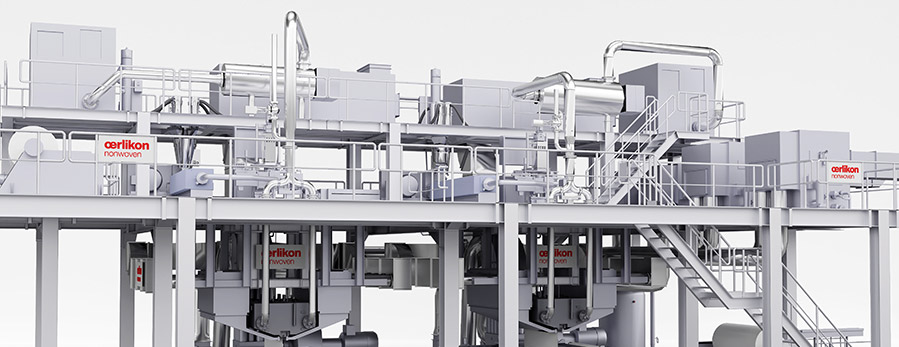

Here, the globally-leading and long-established meltblown technology from Oerlikon Nonwoven will be deployed. In a special, patented process, the fibers laid into a nonwoven fabric during manufacture are subsequently electrostatically-charged, before the material is further processed down-stream.

Inquiries from all over the world

“Our patented electrostatic charging ensures that even the smallest particles, and therefore also viruses, are drawn in and absorbed by the nonwoven fabric for several hours. As a result of the comparatively loose formation of the fibers, the wearer can nevertheless breathe in and out easily”, explains Rainer Straub, Managing Director of Oerlikon Nonwoven with pride. And rightfully so. Because Oerlikon is currently dispatching one meltblown system after the other. “We identified the situation early on and have adapted to demand. We started manufacturing in advance at the beginning of the year and can now start reliably delivering and quickly assembling systems and, due to our global Oerlikon Manmade Fibers segment network, we are able to offer the necessary service as well”, explains the experience engineer. Currently, the company is receiving inquiries from across the globe, but specifically also from Europe and from Germany itself.

“The Federal States all currently want to be self-sufficient in order to better control the so-called critical infrastructure in the future. The investment program announced by Germany’s Federal Minister for Economic Affairs Peter Altmaier this week will additionally boost the demand for our meltblown technology”, continues Straub.

European market for protective masks with a promising future

Those responsible at Oerlikon Nonwoven and FleeceforEurope, which will primarily focus on producing high-end nonwovens, and Lindenpartner, which will manufacture and distribute the protective masks, are certain of one thing: the market for protective masks has a very promising long-term future in Europe. What has been commonplace in Asia for many years now will also become normal in Europe. People will be increasingly wearing face masks when venturing out, in order to better protect themselves against health risks such as the current pandemic and also against increasing environmental pollution in the form of fine particles and exhaust fumes in the future.

“We didn’t know what meltblown technology was three months ago. We helped our customers procure protective masks, at the same time discovering the in part hair-raising conditions in the global markets”, explains Marc Kloepfel, CEO of the Kloepfel Group. According to him, around 200 businesses in China were manufacturing protective masks until 2019, a figure that has meanwhile risen to include thousands of micro-producers. “And there is a lot of very poor quality on the market and, unfortunately, counterfeits as well. But customers from all over the world are knocking on the door with bags of cash and buy everything they can get their hands on – even items that may have been stolen further up the supply chain.”

The prices have practically exploded. “While masks used to cost ten cents to purchase, prices has risen to two euros or more during the coronavirus crisis”, explains Philipp Heymann, CEO of Lindenpartner. However, there is – as in the case of many other industrial and consumer goods – a huge level of dependency on Asia, and China in particular, among Europeans and Americans. In order to become competitive here, the focus will be on state-of-the-art production processes for manufacturing protective masks. “At the end of the day, we will be able to manufacture products in Germany at Chinese prices as a result of our automation technology”, explains Heymann.

Medical face masks from a vending machine

Mask producer Lindenpartner has already secured supplies of nonwovens and will be producing face masks for the European healthcare sector over the coming weeks. To fight the coronavirus pandemic, Lindenpartner is planning to install 100 self-service face mask vending machines in Germany over the next four weeks, positioning them in publicly-accessible places such as shopping centers and airports, for example. FFP2 masks will initially cost around five euros from vending machines. As soon as Lindenpartner is able to manufacture the masks with its own nonwoven fabrics, prices will fall to approx. 2 to 3 euros