#Nonwoven machines

Oerlikon Nonwoven takes part in FILTECH in Cologne

Filtration: Leading meltblown solutions for the highest demands

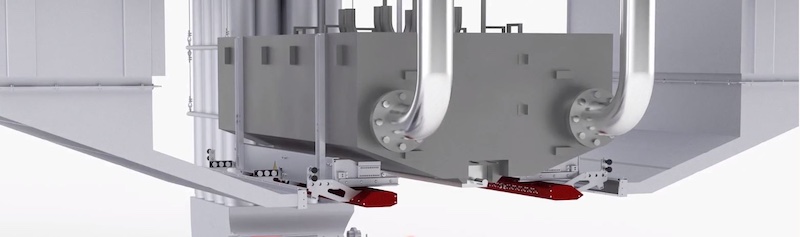

Oerlikon Nonwoven meltblown technology enables the efficient and simple production of unique and highly sophisticated nonwovens for filtration, insulation and sorption applications. The polymers used for the production of filter media and membranes are just as diverse as their areas of application. The spectrum ranges from classic polyolefins (PP, PE) through PET, PLA, PBT and PA to speciality plastics such as PPS and TPU. All these and other raw materials can be safely processed using the Oerlikon Nonwoven Meltblown process.

With the Edana Filtrex Innovation Award-winning hycuTEC hydrocharging technology for the production of highly efficient electret filter media, the pressure loss of a typical FFP2 filter medium can be reduced to less than a quarter. "Filtration efficiencies of over 99.99% are easy to achieve with typical filter media of around 35 g/m² with a maximum pressure loss of 35 Pa," explains Dr Ingo Mählmann, Director Sales & Marketing Oerlikon Nonwoven. "What's more, this innovative process eliminates the need for an additional drying process for the production of high-separation electret filter media for most applications," he continues.

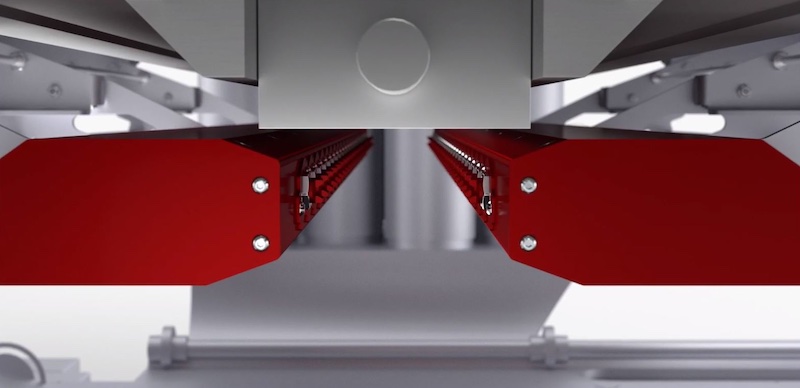

Spunbond solutions: High-performance technology for filter applications

Spunbond products are becoming increasingly important in filtration applications - both as backing materials for filter media and as the filter media themselves. Thanks to a nonwoven structure tailored to their specific tasks, customer-specific requirements for different functions can be realised; it is also possible to combine different functions in one layer. In particular, many years of experience in the field of bicomponent spinning processes enable the design of completely new nonwoven structures and thus the fulfilment of different functions in one material. With the Oerlikon Nonwoven Bico spunbond process, different fiber cross-sections can be combined, but also different fibers can be produced simultaneously from one or different polymers on one system. The spectrum ranges from classic core-sheath and side-by-side bico filaments to splitable fibers and so-called mixed fibers.