#Knitting & Hosiery

SHIMA SEIKI announces new design software and web services

1. SDS®-ONEAPEXFiz™

Fiz is the latest addition to SHIMA SEIKI’s proven SDS®-onE APEX series design system lineup, but with an unprece- dented twist. Whereas previous APEX-series design systems were offered as an all-in-one proprietary hardware/software package, for the first time in its nearly 40-year history of design system development, SHIMA SEIKI has released its new SDS®-onE APEX Fiz™ as subscription-based design software that can be installed on cus- tomers’ individual computers. Maintaining proven functions that have made the SDS®-onE APEX series so popular with fashion designers, with Fiz those strengths are now enhanced with the added versatility to adapt to different work styles and environments of the “new normal.” Fiz is furthermore available in 5 different flavors that can be selected according to the customer's needs, from Fiz Design Pro to Fiz Design Jr (Please refer to the separate docu- ment: Fiz_flavors_e.pdf).

Fiz software supports the creative side of fashion from planning and design to colorway evaluation, realistic fabric simulation and 3D virtual sampling. Virtual sampling on Fiz and other APEX series is a communication tool that is not only an accurate representation of the product, but it also digitally bridges the gap between the studio and the fac- tory. By sending data to the knit manufacturer it can be converted to machine programming data, shortening lead times and allowing the production of items faithful to their design as originally intended by the designer. That accu- racy allows virtual samples by SHIMA SEIKI to be used effectively as prototypes, replacing sampling and consequent- ly reducing time, cost and material that otherwise goes to waste. Fiz thereby fulfills its role as a spearhead for realiz- ing sustainability in fashion.

“Fiz” is based on “Fizz,” the sound or state of carbonation. It represents energy, excitement, vitality and spirit. As the name of SHIMA SEIKI’s new design software, Fiz symbolizes inspiration for creativity as it bubbles up like a well- spring and makes designs sparkle!

2. yarnbank™

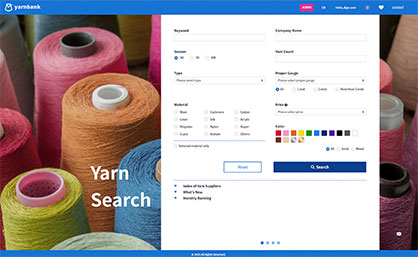

yarnbank™ is the world’s first online web service for searching and viewing the latest yarns, developed with cooper- ation from yarn companies from around the world. Registered users have free access to the yarnbank™ archive of yarn information and digital yarn data. Users can also download yarn data for free, for use in fabric simulation and virtual sampling on Fiz and SDS®-onE APEX4, avoiding the need to scan yarn on their own. By using yarn that is used in actual production, knit manufacturers and apparel companies can furthermore rest assured that the simulations created using yarnbank™ are not merely realistic images but accurate representations using yarn that can actually be purchased and used in production. yarnbank™ also serves as a new promotional platform for yarn companies with the opportunity to present their yarns directly to their customers. In that respect, yarn companies can reduce their dependence on traditional sample books as a means to promote their products, saving time, cost and material and doing their part for sustainability. yarnbank™ brings together each player in the supply chain—spinner, knit manufacturer and apparel company—and connects them digitally.

3. SHIMANAVI™

The SHIMANAVI™ e-learning system allows APEX series users to experience online training when and where it is convenient, and at their own pace, supporting new work styles and environments such as teleworking and telecom- muting. Several courses are available in different languages to suit the needs of individual customers as well.

SDS®-ONE APEX Fiz™ Details

Product Description:

SDS®-onE APEX Fiz™ Subscription-based design software

Software Variations:

Fiz Design Jr.

Fiz Design-Standard

Fiz Design-Knit

Fiz Design-Weave

Fiz Design Pro

Release date: October 2020

URL: https://www.shimaseiki.com/fiz

yarnbankTM Details

Product Description:

yarnbank™ Digital yarn-sourcing website

Release date: September 2020

URL (coming soon):

https://online-services.shimaseiki.com/en/

SHIMANAVI™ Details

Product Description:

SHIMAnAVI™ e-Learning web service

Release date: October 2020

URL (coming soon):

https://online-services.shimaseiki.com/en/