#ITMA Asia + CITME 2022

Innovative textile production and finishing: Mahlo presents new solutions at ITMA Asia 2023

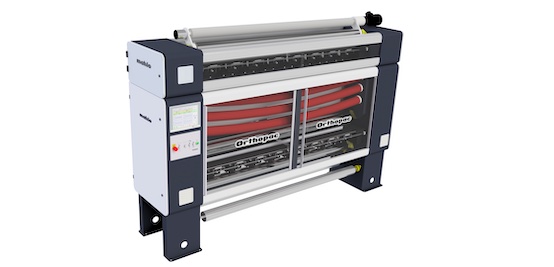

In the textile industry, the name Mahlo stands for high-quality automatic straightening systems and process control systems. The recipe for success of the experts from Germany is almost 80 years of experience paired with the latest technological developments. At the Mahlo booth H5-C28, the team will therefore present the latest development in weft straightening systems alongside established systems: The Orthopac RXVMC sets the highest standards in warp detection and correction.

"For many of our customers, the issues of quality, energy savings and return on investment play a major role," says Product Manager Clemens Kaplan. "Our goal is to combine all three points in our systems and thus optimize the customers' production process." Among other things, the focus is therefore on the new X-Series concept for forward control of knitted fabrics with strong drafting. The Orthopac RXVMC straightening machine, which was presented for the first time at this year's ITMA Europe, can remove distortions in textile fabric webs even faster and more precisely.

New straightening concept: more precise and faster response

"In the new straightening concept, special attention was paid to the straightening mechanics and their interaction with the analysis electronics of the probe system," explains Sales Manager Thomas Höpfl. The control concept is also new. A probe group at the leveler infeed detects distortions even before they reach the correction rolls. In this way, the rolls are brought directly into position and the fabric is corrected from the very first centimeter. A scanner group at the outfeed also detects possible residual distortion, which is corrected at the second straightening module. This enables an even more precise and faster response when it comes to reacting to rapidly changing distortions. The Orthopac RXVMC therefore shows its full strength when straightening knitwear and fabrics sensitive to distortion.

Also contributing to high-quality textile production and finishing is the Famacont PMC for controlling weft and stitch course density, which will also be on show at ITMA Asia. The Famacont PMC-15 uses a sensor to measure the yarn or stitch density and compares it with the target value stored in the recipe data management system. The detected deviation of the yarn density from the target value is used to fully automatically regulate the leading during the needling process on the stenter frame. Interested parties can have the mode of operation explained to them at the Mahlo booth with the help of a demo tower and their own or provided fabric samples.

Digital environment

Another major topic remains Industry 4.0, because the best measured data is of no use if it cannot be utilized. Mahlo has continuously developed its digital environment mSmart. "Our systems generate data that the customer can use immediately to regulate goods on-line. At the same time, all measured values are backed up in our data management system mLog enhanced and can be retrieved at any time. With this historical data, processes can be optimized and weak points in the process can be minimized," explains Sales Manager Thomas Höpfl.