#ITMA Asia + CITME 2018

Bräcker at ITMA ASIA 2018 in Shanghai

Bräcker’s products enable spinning mills to increase their production output at an efficient price-performance ratio. The company will demonstrate the ability to generate additional customer value, by utilizing its expertise in ring spinning.

The surface treatment of the ONYX travellers facilitates a higher efficiency. The improved gliding characteristic allow for an increase of the spindle speed by up to +1000 rpm and prolongs the life of the traveller by up to +50%. On top of that the running-in period is considerably reduced.

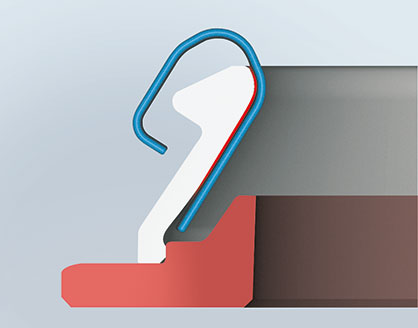

The large contact surface between SFB traveller and ORBIT ring allows for increased spindle speeds even with fibers like Viscose or with fibers, tending to thermal damage, e.g. Polyester.

Higher traveller speeds of 10 - 20% are achieved compared to the T-flange ring / C-shaped traveller system. To cover the new demands, the SFB traveller portfolio was substantially expanded in regards of traveller profiles and weights.

BERKOL® multigrinder MGL and MGLQ – the all in one grinder

The entire range of top rollers and long cots used in a spinning mill can be processed on only ONE single machine. Any execution of center guided top roller is ground fully automatically on the BERKOL® multigrinder. The multigrinder MGL/ MGLQ is a very flexible grinding machine for smaller and medium sized spinning mills with up to 50’000 spindles. Operating the machine is done only from the front side of the machine. The optimal ergonomics of the multigrinder allow for its efficient operation.

A detailed overview about the full product range of Bräcker can be found under www.bracker.ch.