ITMA 2023

Novelties at ITMA Milan 2023

Graf just unveiled its latest innovations on June 8, 2023, at ITMA 2023 in Milan, Italy.

Across its two booths, one dedicated to spinning solutions and the other to nonwoven, Graf proves its leader position with solutions for every application: No Limits in Processing Fibers.

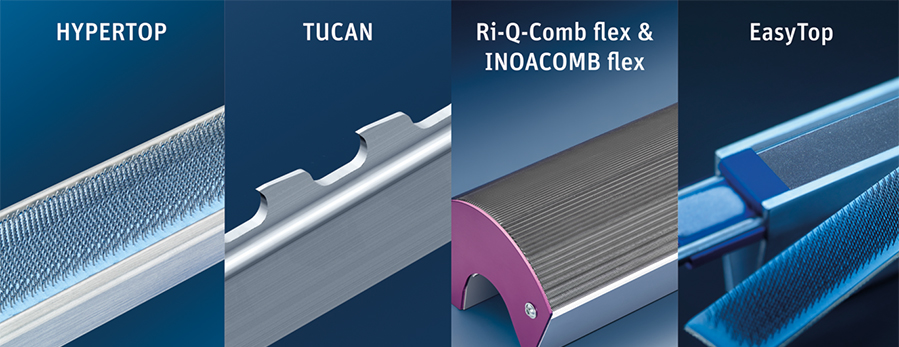

Flexible flat: HYPERTOP

With its patented multi-zone setting pattern and optimized tooth geometry, HYPERTOP offers unparalleled good fiber savings of up to 0.5% while ensuring constant and optimal yarn IPI values.

Benefits:

• Up to 0.5% good fiber savings versus resist-O-top C-55

• Yarn IPI quality at optimal constant or better level

• Payback within one month

• Higher card throughput or higher trash cotton possible

Carding wire: TUCAN

Say goodbye to grinding with cotton and blends ? Ne 60. TUCAN metallic card clothing has been specially designed to handle up to 1’100 tons of material without any grinding required.

Benefits:

• Grinding-free during 1 100 tons with cotton & blends ? Ne 60

• No grinding equipment, no skilled labor, no downtime, no maintenance, no trouble

• Yarn IPI quality at optimal constant level

Circular comb: Ri-Q-Comb flex

This combined system from Graf circular comb and Rieter comber E90 delivers unparalleled performance and reliability, with optimized and consistent IPI values customers can rely on.

Benefits:

• Graf as no. 1 in combs + Rieter as no. 1 in combers = best system

• Needle finish ensures best and constant IPI values and fewer winding cuts

• Best IPI and yield with +8% combing area and 130° surface

• 50% longer lifetime of CUTTYSHARP alloy minimizes investment

• Highest production rates (600 nips/min) ensured by robust lightweight design

Circular comb: INOACOMB flex

With the innovative needle finish system, better IPI (imperfection) values and fewer winding cuts are ensured over the lifetime of the equipment.

Benefits:

• Needle finish ensures best and constant IPI values and fewer winding cuts

• Optimal IPI and yield with 120° combing surface

• 50% longer lifetime of CUTTYSHARP alloy minimizes investment

• Lightweight design and precise counterweight deliver high production rates (max. 500 nips/min)

Flexible flat: EasyTop

EasyTop increases quality and saves time. The innovative magnetic adhesion technology reduces downtime by 30% during reclothing of aluminum flat bars.

Benefits:

• Optimal carding gap resulting in best IPI yarn quality

• Reclothing on the card by mill’s own staff

• 30% reduced downtime for reclothing

• No investment in equipment (DAM, DSM, DEW)

• No equalization grinding after reclothing (DEW)

Service machine: DAM 35 flex flat

This 2-in-1 stripping and clipping machine for flexible flats delivers a precise and stable carding gap and allows a fast changeover.

Benefits:

• Contributes to precise and stable carding gap

• 2-in-1 machine for stripping and clipping flexible flats of any kind

• Fast change-over from one flat type to another

• Safe workplace

Recycling card clothing package

The new recycling card clothing packages enable mills to transform recycled cotton, cotton blends and man-made fibers into high-value yarn up to Ne 30.