#ITMA 2019

On the way to an evergreen with ecological GREENDYE

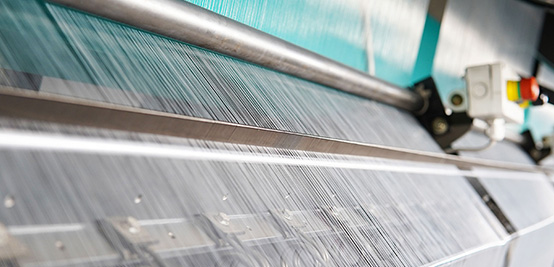

KARL MAYER launches eco-friendly indigo dyeing technology at ITMA 2019, booth 8.0/B107

At ITMA 2019, KARL MAYER launches GREENDYE, an innovative technology for producing jeans fabrics with minimized ecological footprint, thus, opening up another market sector, SUSTAINABLE DENIM.

Dyeing in nitrogen atmosphere

The nitrogen technology ensures less environmental impact and more efficiency during indigo dyeing. With its high concentration in the dye bath and under nitrogen atmosphere, the dye diffuses and migrates more intensely into the fibre than in case of conventional comparable procedures. The yarn can absorb three times more dye in a dye vat. In this way, it is possible to reduce the number and length of vats, with positive effects for the environment. The chemical consumption can be reduced considerably, a minus of 50% is possible when using hydrosulphite and caustic soda, and there is also less yarn waste. Moreover, due to the good fixation of the dyestuff on the fibre, considerably less water is required during the washing process.

Production with reproducible parameters

KARL MAYER took over the patents for the innovative indigo dyeing technology from MASTER in 2018. There followed extensive works for the further development and fine tuning. One of the milestones in this context was the putting into operation of a pilot machine at the Denim Competence Center in Mezzolombardo, Italy, at the beginning of this year.

Fabric samples, an animation of the machine and its contribution to the topic of sustainability belongs to the highlights of KARL MAYER’s exhibition stand 8.0/B107 at ITMA 2019. Further steps are already planned. As from September 2019, KARL MAYER will have a new Denim Customer Center, and wants to invite the sector to carry out processing tests on the innovative nitrogen unit.

More about SUSTAINABLE DENIM:

https://www.karlmayer.com/en/sustainable-denim