#ITMA 2019

CREALET with new corporate design at the ITMA 2019

The trade fair focus on INNOVATING THE WORLD OF TEXTILES precisely reflects CREALET's core business. The ITMA is thus the ideal platform for CREALET to demonstrate the entire portfolio, to exchange ideas with experts and customers and to get in contact with young talents.

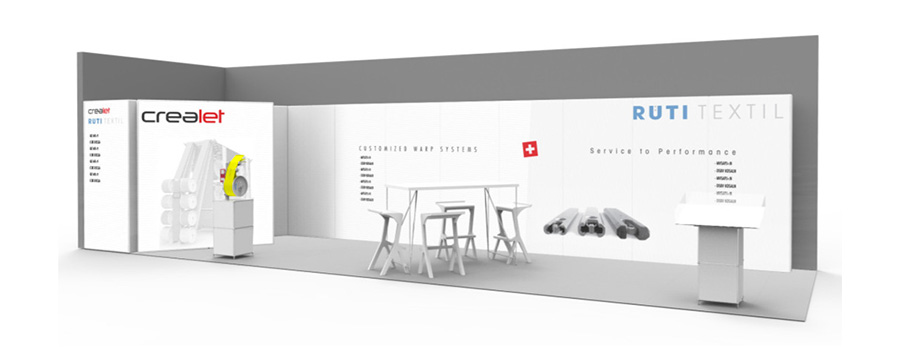

The two independent companies CREALET AG and Ru?ti Textil GmbH seize the opportunity of a joint trade fair participation. Both are experts in the weaving process with the use of the latest technologies in the field of industry 4.0.

Crealet AG is specialized in customized warp feed systems and Ru?ti Textil GmbH is expert in development tasks of the weft insertion.

Introduction of CREALET’s new appearance

CREALET is thrilled to announce the introduction of the new corporate design, with a refreshed logo. The new design is in line with the evolution of the company with new products and services under the leadership of the next generation of leaders.

All areas, processes and communication channels will be equipped with this new design - but it is impossible to update all at the exact same time.

CREALET presents itself with a new look on the pulse of the time

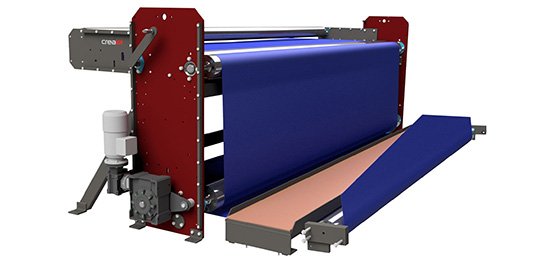

Apart from the new, fresh appearance the visitors can expect new and inspiring features for optimizing warp tension control of small warp beams. CREALET’s core competence are special solutions in warp tension control for narrow and wide weaving machines.

New features for warp tension control

CREALET develops drives and controls that allow a fast and precise positioning and synchronized movements that support highest dynamics in an intelligent system network.

LT control unit

The new LT controller is a control unit for warp tension control. It is suitable for various areas of application where the measurement and control of the warp tension is required. Typical areas of application are the control of small warp beams in ribbon weaving or selvedge bobbins on wide weaving machines. It is also used for warp feeding by feed rollers when weaving from creel.

The LT control unit is designed for continuous operation in the Textile Industry, with features for a quick setting. The LT control unit contains a display which shows measured warp tension, active functions/settings and display settings in the menu.

Industry 4.0 and the Internet of Things (IoT)

A rapidly advancing industrial digitization and trends like smart factory and the Internet-of-Things are challenges and prospects CREALET will handle together with qualified partners to expand CREALET’s position.

A first step in this direction has already been realized with a customer project in the area of safety-relevant narrow fabrics.

Innovation with sustainability - a new lease of life for your machinery

CREALET specialises in existing warp let-off devices in narrow and wide weaving machines that no longer meet the requirements of modern, efficient drive and control components.

This reduces the amount of work required and improves fabric quality.

CREALET’s service benefits in:

- increasing automation of existing machinery

- improving reliability

- raising quality and productivity

- extending equipment lifecycles

- Electronic let-off and cloth take-up devises

- Warp beam devices on weaving machines

- Warp beam stands for one or more warp beams

- Yarn feeding devices for weaving from creel

- Electronic selvedge thread let-off’s