#ITM 2024

SAVIO’s next destination: ITM Türkiye 2024

Industry leaders and key players will have the opportunity to get together in Turkey, the earth of Eurasian textile hub, to explore new business opportunities, forge worldwide connections, and showcase the latest products, services, and technologies in the textile industry.

Savio will display its latest product range solutions which testify Savio’s dedication to innovation technology and strong partnerships across the industry. Savio looks forward to welcome visitors at Vandewiele Group booth in Hall 7 booth 710A for discovering more about our winding, twisting and air jet spinning innovations.

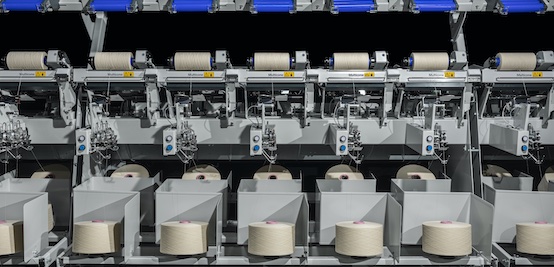

NEXT DESTINATION: PROXIMA Smartconer®

The new winding machine Proxima Smartconer® is setting the benchmark in Savio automatic winding.

Savio has combined the name Proxima with Smartconer®: it stands for a high-tech winding machine, capable of perfectly adapting to demands of Connectivity, Industry 4.0 and Industrial Internet of Things.

Thanks to the innovations, spinners will get a machine featuring high-tech capabilities, thanks to a design with a strong focus on the main benefits for customer’s competitive advantage: high productivity, low energy consumption, premium yarn quality, automation, and data connectivity.

Proxima Smartconer® has been designed with the foremost attention to the customer’s needs in the optimal utilization of a winding machine.Investing in equipment that enables to work faster and reduces manual and repetitive tasks, can increase both efficiencies and overall productivity. The same applies to a new equipment that does more of what is needed, faster, safer, with better quality but with less waste, less maintenance, and less resource usage.

SAVIO’S LYBRA Smartspinner®: WE SPIN DIFFERENT

Savio’s new air-jet spinning machine: LYBRA Smartspinner®

With Lybra Smartspinner®, Savio says they spin different with a versatile and smart machine. Savio’s air-jet spinning machine has been developed with an original spinning technology to serve our customers in specific applications of textile production: knitting, home textiles, sunshades. Air-jet spun yarn has a soft and smooth character, perfectly adapting to creating functional & fashionable fabrics.

With LYBRA Smartspinner®, they want to offer their customer a versatile, flexible, cost saving and easy-to-use machine. Air-jet spinning offers to yarn manufacturers the opportunity to produce yarn at high production rates and low processing costs. The air-jet spinning technology use the same preparation of the conventional ring spinning. This processing works directly with slivers instead of roving, integrating three textile processes: roving, spinning & winding.

Space needs for air-jet spinning is 25-30% less than for ring-spinning equipment producing the same capacity, thereby reducing building costs. Also, a smaller area requires less climate control and reduced operating personnel. This results in further substantial savings, maximizing the return on investment.