#ITM 2018

SANTEX RIMAR GROUP and HAS GROUP at ITM 2018

CSM6

New generation vertical Brushing Machine with brand new technologies applied: Moving parts and Free action.

Thanks to these two features customers will solve the wing-gap problem and be able to obtain different brush effects on the same fabric.

DECOFAST 3.5

The evolution of the continuous decatizing process under pressure for finishing Polyester-Viscose, Polyester-Cotton, Wool & Wool Blend and Synthetics Blends, knitted and woven fabrics adds value to the whole finishing process. Sperotto Rimar Decofast 3.5, with already almost 140 units installed worldwide, is the answer to the actual market demand of growth through value.

HEAT RECOVERY SYSTEM

Another product to be exhibited at the fair is Electrostatic Filter and Heat Recovery System. The unit is produced to heat the environment in the cabins and to save energy taking advantage of the hot air coming from exhaust shafts of Ram machines working at very high temperature. RAM-

X

RAM-X series stenter frames offers maximum operating efficiency for the best possible quality results with minimum energy consumption for treatment of textile products. The new reinforced chain and rail system is the benchmark for heavy weight fabrics such as knitted, woven, nonwovens, denim and technical textiles applications.

Thanks to the modular and compact machine design, RAM-X is easy to ship and needs less maintenance. RCM-D

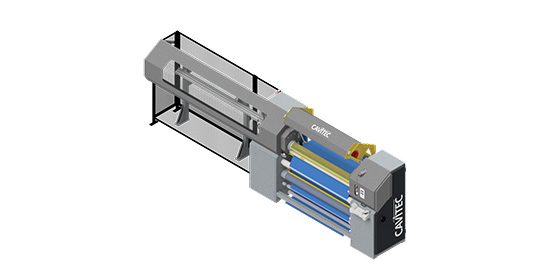

Suitable for all kinds of natural and synthetic woven and knitted fabrics, RCM-D guarantees raising flexibility.

Drums and working rollers can be operated in different rotation directions and pile and counter pile raising rollers work at independently adjustable speed. Double drum raising machine alternatively consists of 24 or 28 working rollers.

STM-X

New STM-X stainless steel improved in terms of corrosion-oxidation resistance and makes the machine lifetime longer. Less maintenance is required.

Patented storage chain automatically reduces the number of sticks and adjustable stick distance solves the rubbing issue with sensitive fabrics, especially digitally printed fabrics.