#ITM 2016

Setex will demonstrate the adavantages of OrgaTEX X1 software at ITM

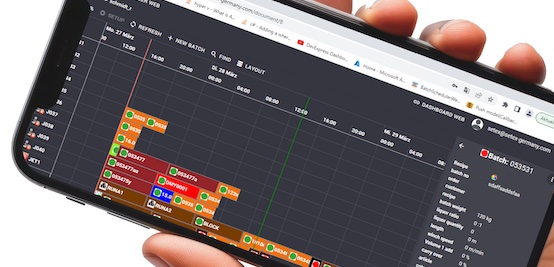

The process and recipe handling - constantly used parts of the software - is new designed. The modules provide impressive new features to simplify complex production steps, to save expert know-how systematically and to optimize resource efficiency.

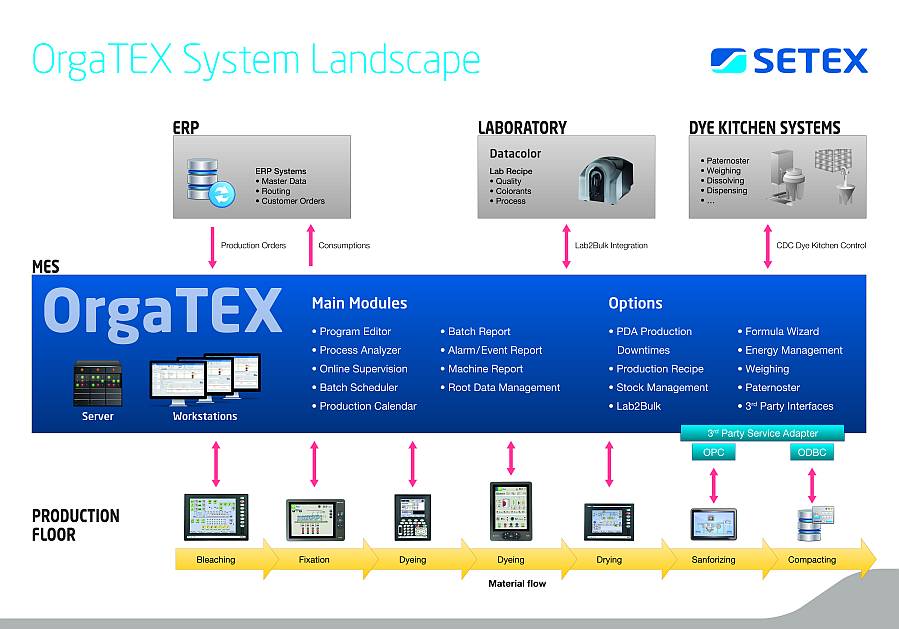

OrgaTEX X1 is also highly customizable. Although dyeing machines significantly lowering liquor ratio and requiring less chemical quantities, this software suite still can reduce dyeing time and production cost, optimize the throughput and expose weak spots and bottlenecks. OrgaTEX X1 has enhanced adapters to communicate with dyeing, continue and finishing machines for ecological and cost improvement: Each machine can be considered within the overall energy management concept.

Intelligent integration of dosing systems saves chemicals and water. The operation is independent of operator skill.

The philosophy of the new software is to bring the best-in-class recipe tools but still providing the flexibility of using simple flat recipe methods. As such, converted information and experience is usable as formulas, wizards assist the creation of formulas and there are predefined formulas shipped with the system.

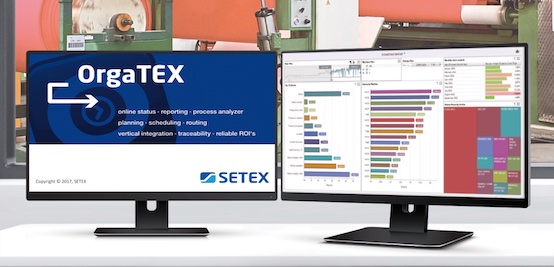

Pic: OrgaTEX X1 recipe tool