#INDIA ITME 2022

India ITME 2022: Rieter strengthens success of spinning mills

- Autoconer X6 – key machine for highest efficiency

- Compacting solutions – full flexibility adds competitive edge

- Spin it again – recycling expertise for rotor and ring yarns

- ESSENTIALorder – purchasing parts with a few clicks

- ROBOspin – the solution for personnel shortages

- SSM NEO-FD – proven technology for efficient twisting production

- Temco CoolFlow disc – innovation that delivers longer lifetime

Autoconer X6 – Key Machine for Highest Efficiency

The automatic winding machine Autoconer X6 perfectly completes the Rieter ring and compact-spinning systems. The machine serves as the final quality assurance in the ring and compact-spinning process and is key to the performance of the subsequent process stages. The Multilink system with Multilot offers maximum flexibility to handle a different type of yarn.

The latest splicer generation OZ1 and OZ2 provides an optimum splice quality based on an open prism. With only two prisms spinning mills can splice the entire spectrum of cotton yarns as well as blends. They are also used for the splicing of cotton-based elastic core yarns in combination with the Elastosplicer. The splice zone exhibits an impressive elasticity in the fabric.

Full Flexibility with Compacting Solutions

The Rieter compacting devices – COMPACTapron, COMPACTeasy and COMPACTdrum – are the right solution for every application. Spinning mills can change quickly between ring and compact yarn and offer customers a broader product range. This gives them an edge in the market.

Spin it Again: Recycling Expertise from Rotor to Ring

Rieter offers solutions for the integration of recycled raw material into yarn production to help close the textile loop and make fashion more circular. Both rotor and ring yarns can be produced with a considerable amount of mechanically recycled fibers. The result is promising: Garments made of challenging post-consumer material can be attractive for both consumers and the environment.

ESSENTIALorder – Purchasing Parts with a few Clicks

Based on existing customer information, the webshop ESSENTIALorder visualizes which Rieter machines and systems are available inside each spinning mill. It therefore offers a personalized shopping experience and facilitates order management, enabling spinning mills to optimize their internal stock levels. ESSENTIALorder is available 24 hours a day, seven days a week.

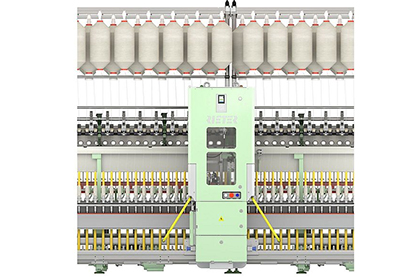

ROBOspin – the Solution for Personnel Shortages

The piecing robot ROBOspin reduces personnel requirements in the ring spinning section by 50%. The robot also attains productivity increases thanks to higher spindle speeds at equal or higher efficiency.

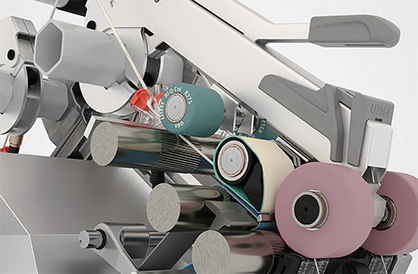

SSM NEO-FD for Efficient Twisting Production

SSM is presenting NEO-FD, the assembly-winding machine for precision wound packages for twisting. It meets all requirements for efficient production. The machine features the auto-doffing option and the online back-pressure system for low and high package densities. With ergonomic design and proven technology, the machine cuts maintenance and service costs to a minimum.

Temco CoolFlow Disc with Longer Lifetime

Temco’s CoolFlow texturing discs offer longer lifetime thanks to a brand-new geometry and the latest polyurethane technology. The texturing discs now generate a disc surface that operates at a lower temperature, resulting in slower ageing and abrasion. Further benefits are more stable yarn quality, higher productivity, and an overall process cost reduction.

Visit Rieter at INDIA ITME 2022 at India Expo Centre & Mart, Greater Noida, Uttar Pradesh 201306, India from December 8 – 13, 2022 in hall 10 at booth H10C11.