#IDEA 2022

IDEA 22: Reifenhäuser Reicofil shows broad portfolio of high-performance and sustainable nonwovens

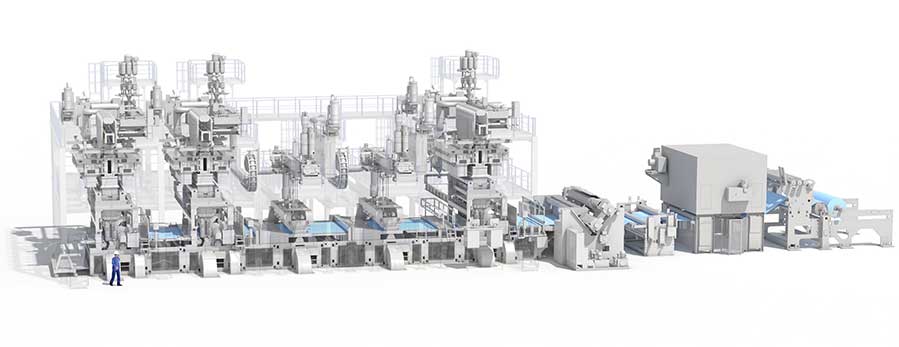

"We offer the appropriate line technology for almost any application. From soft and bulky High Loft nonwovens, sustainable and bio-based fabrics to high barrier nonwovens with optimized properties and reliable filter characteristics to nonwovens made from post-consumer waste. With our current RF5 machine generation, we are also setting the benchmark in terms of quality, performance, availability, efficiency and machine intelligence," explains Markus Müller, Vice President Sales & Marketing Reifenhäuser Group.

In terms of sustainability, Reicofil offers various approaches to save fossil raw materials, such as the processing of bio-based raw materials as an ecological alternative - for diapers, for example. Here, the topsheet material, made of bulky, soft, and industrially compostable High Loft nonwovens, meets maximum hygiene requirements. For industrial applications, high- strength nonwovens can be processed even from up to 90% PET flakes from post-consumer waste. This is how Reicofil shows perfect ways to combine sustainability and high-performance nonwovens.

Another highlight is the so-called BiCo technology. In this process, two different raw materials are combined in one fiber in the spunbond process, creating a bimetal effect and causing the fiber to crimp. This opens the door for manufacturers to completely new product properties that are unattainable with monofibers.

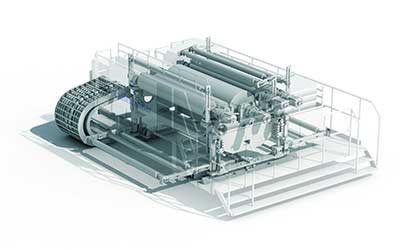

Nonwoven-film composites with exceptionally low grammage

For the medical sector, Reicofil will showcase its leading solutions for high- barrier medical protective clothing and - together with its sister business unit Reifenhäuser Cast Sheet Coating - the pioneering Ultrathin Coating production process, which enables customers to produce film-nonwoven- composites more cost-effectively and thus competitively. The Corona pandemic and current supply bottlenecks have exposed the dependence of companies on global supply chains. This situation is both a warning signal and an opportunity to fundamentally strengthen local semi-finished product production. The jointly developed process achieves significant cost savings and easier line maintenance by eliminating the need for hot melt adhesives. With the patent-pending Ultrathin Coating technology, producers reduce film grammage by 66 percent. Thanks to the perfectly compatible combination of Reifenhäuser nonwovens and extrusion coating lines, customers thus receive seamless semi-finished product production.

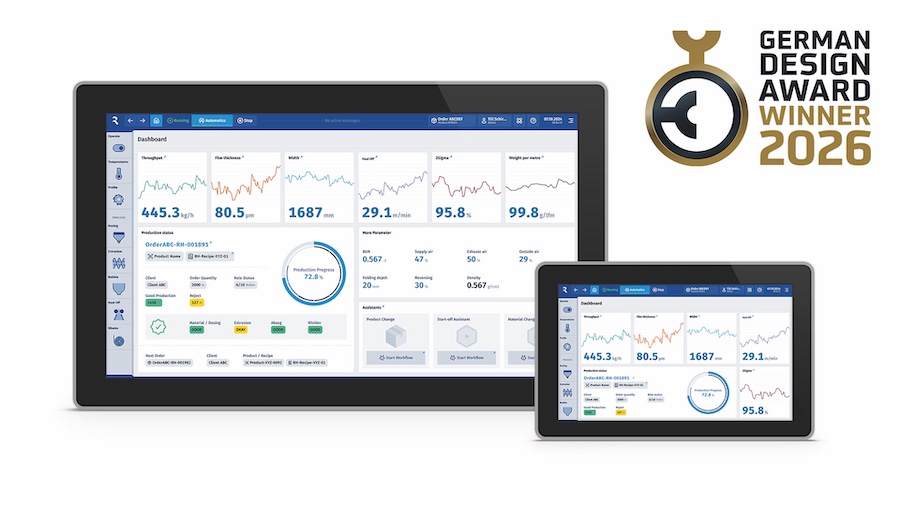

Smart digitization with full data sovereignty

With the c.Hub, the new data platform of the Reifenhäuser Group, Reicofil offers its customers a digitization solution that is tailored to the requirements of nonwovens production. Customers can securely connect, centrally store and easily analyze data from their Reicofil machines, peripherals, ERP and MES systems via the c.Hub middleware. Together with various software bundles, c.Hub is offered as an on-premise solution. It can be deployed locally and remains under the full data sovereignty of the user. Via the web-based ExtrusionOS user interface, customers can keep an eye on their production and the status of their machines wherever they are. The ExtrusionOS software packages offer transparency from the first to the last meter, faster defect troubleshooting, and complete traceability of key quality parameters.