#Dyeing, Drying, Finishing

Monforts automation reinvigorates Pincroft line

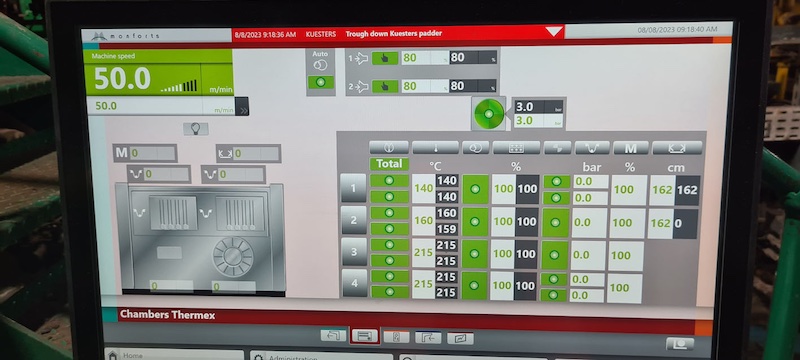

First installed in 2007, the line has been upgraded to match the performance of the very latest Monforts Thermex lines that are equipped with advanced automation features providing machine operators with full control over the entire system.

The modernisation project included new control cabinets, gear motors for the fabric transport drives and PC, PLC control, touch panels and frequency inverters.

The new control cabinets were supplied fully pre-assembled from the Monforts HQ in Mönchengladbach, Germany, for direct connection to the line.

In addition, Pincroft has installed a new combined heat and power (CHP) plant at the site and is now able to produce 67% of its own electricity and recover heat for use across its textile operations.

Know-how

With over 130 years of accumulated know-how in the bleaching, dyeing, printing and finishing of fabrics, Pincroft has an annual production capacity of 50 million metres.

Its meticulous pre-treatment processes, including brushing, singeing, desizing, scouring, bleaching, and mercerising, ensure that fabrics are primed for dyeing and printing, enhancing their quality and performance.

Drawing on a vast knowledge in commission textile dyeing, eco-friendly dyeing methods and advanced lines ensure precise and consistent colour shades meeting the most challenging fabric requirements and as a specialist in bespoke commission printing, services span everything from camouflage printing for global military forces to designs for home and workwear.

Mechanical and chemical finishing services can further transform textiles and enhance their inherent properties and the company is Europe’s leader in flame retardant fabric treatments, with its Proban® treated textiles ensuring ultimate protection with outstanding comfort, appearance and durability.

After joining forces with Carrington Textiles in 1998, the company has been an integral part of one of the largest suppliers of workwear, flame retardant, waterproof, defence and sustainable fabrics to some of the biggest companies and organisations in the world.

Since then, export business has significantly expanded to over 80 countries and the two companies enjoy a particularly strong position in the supply of camouflage and uniform materials to armed forces around the world, including the UK and Dutch Ministries of Defence, as well as the Finnish and Estonian armies.

Reliability

The upgraded Thermex system at Pincroft’s Adlington plant now achieves unrivalled reliability even at maximum fabric speeds, for exceptional cost-effectiveness when dyeing both large and small batches of woven fabrics.

“Our machines are built to last and known for their robustness and long service life,” says Monforts Area Sales Manager and Head of Spare Parts and Retrofits Achim Gesser. “Textile companies making major capital investments in new manufacturing lines rely on durability from the company’s production ranges, and it’s for this reason that there are currently an estimated 2,000 Monforts machines in operation worldwide – some of which were first installed over 30 years ago.

“This doesn’t mean, however, that they can’t benefit from many of the advances in performance and automation we have subsequently made. The retrofitting of specific modules with new control and drive technology – going far beyond the basic replacement of spare parts – can have a significant impact on the performance of an existing line and especially maximising energy savings.”