#Dyeing, Drying, Finishing

Denim art from Mexico

For years, the company has been developing and producing high quality denim. From fibers, yarns and fabrics to casual wear, ARTE EN DENIM creates textile products of outstanding quality. The company's team of experts assists its customers with product design and development, as well as providing comprehensive denim treatment advice on wet and dry finishing, logistics and shipping, and offers other customized services to meet the needs of its domestic and foreign customers. ARTE EN DENIM's expertise and modern, high-quality machinery offer customers the perfect formula for developing, producing and marketing their design ideas.

ARTE EN DENIM employs more than 700 people, including textile engineers, textile designers and certified technicians. A well thought-out human resources development program encourages employees at all levels and contributes to their qualification, training and achievement of degrees in all professional fields. The company's goal is to achieve, with adequate profitability, not only the economic development of the company, but also a better quality of life for its employees.

The company places a special emphasis on innovation, technology, textile developments, and fashionable products for demanding customers such as Workwear Outfitters and Dickies, which specialize in workwear, as well as the U.S. VF Corporation, one of the largest apparel companies in the world and the market leader in underwear, workwear, and backpacks. Reliable and trustworthy relationships with customers are one of ARTE EN DENIM's highest values.

ARTE EN DENIM products include flat woven, piece dyed or yarn dyed fabrics, denim, PFD cotton and garments, mainly denim pants in the Work & Casual Wear segment. The collection includes the Rigida line, made of 100% cotton, which offers robustness and durability in classic denim style, the Comfort line, made of 99% cotton and 1% elastane, and Stretch, which is made of cotton blends with polyester and 2% elastane.

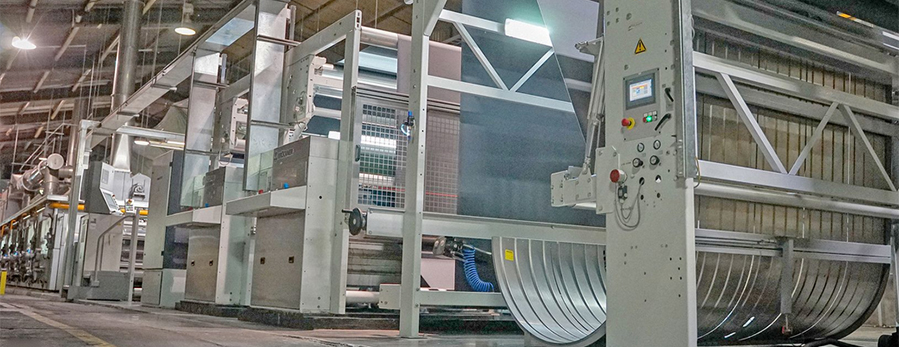

ARTE EN DENIM has chosen a first-class BRÜCKNER POWER-FRAME HN stenter with 2 padders for the production of its high-quality fabrics. The high drying and evaporation capacity of the stenter allows the fastest possible drying of cotton fabrics. Due to the high temperature accuracy in the BRÜCKNER machine, also synthetic fiber mixtures can be heat-set efficiently.

The very homogeneous air flow and temperature distribution of alternately arranged thermo zones and the proven split-flow design with separately adjustable upper and lower air were some of the features which convinced the customer. Reproducible finishing results and the robust construction which does not only guarantee a long service life of the machines but is also excellently suitable to withstand heavy denim fabric are further plus points for the BRÜCKNER stenter.

ARTE EN DENIM is committed to the protection of the environment. This is expressed in its ambitious water recycling system, an environmentally friendly substitution of chemicals as far as possible and a firmly anchored culture of environmental protection in the whole company. In this context it goes without saying that the new BRÜCKNER stenter is equipped with a heat-recovery system (WRG). This system uses the exhaust air heat from the drying process for heating fresh air. The heated fresh air is fed back to the dryer and thus reduces the heating energy demand of the stenter by up to 20 %. The BRÜCKNER ECO-HEAT back-pack heat-recovery system sits directly on the stenter frame and therefore does not need a separate steel structure. The system is equipped with several cassette-type heat exchangers which can be easily removed for cleaning or maintenance purposes.

ARTE EN DENIM is highly satisfied with this high-tech machine which offers best technology, allows an easy control of all necessary parameters and ensures low maintenance costs and appreciates BRÜCKNER as an innovative and reliable partner.