#Digital Printing

Mimaki to launch new product innovations and engage visitors with high-performance, high-value 100 series at virtual drupa

In line with virtual drupa’s goal to help the industry keep in contact, grow their networks and generate leads in today’s challenging times, Mimaki will use the event to demonstrate its latest business-enhancing digital printing solutions and to highlight numerous application opportunities. “Faced with the current circumstances of the Covid-19 pandemic, we all need to adapt and come together to come through this challenging situation,” says Danna Drion, Marketing Manager, Mimaki EMEA. “For the last 12 months, Mimaki has been at the forefront, supporting customers and prospects with virtual events, networking and educational opportunities to overcome the impact and challenges created by the Covid-19 pandemic. Online events remain central to our strategy and virtual drupa represents a key opportunity for us to share our expertise and encourage print service providers to join us and find new ways to drive their business forward.”

The company’s latest “100 series” portfolio will be one of the highlight technologies showcased at virtual drupa. Designed to enable users to drive success amid the current market uncertainty, the new printer series offers high productivity and reliability, extreme flexibility to diversify the application range, as well as a highly competitive price-performance ratio. The Mimaki’s 100 series consists of three models, each equipped with a variety of renowned Mimaki features, including NCU (Nozzle Check Unit), NRS (Nozzle Recovery System), and DAS (Dot Adjustment System).

- Mimaki JV100-160: a roll-to-roll eco-solvent printer, the JV100-160 enables users to achieve high quality solvent printing at an entry-level price. The printer adopts the recently developed, fast drying eco solvent ink “AS5”, available in both a dual CMYK 4 colour mode and 8 colour mode (CMYK Lc Lm Or Lk). Besides reducing graininess and allowing for fine details even when printing images with high volumes of ink, the new AS5 ink has superior scratch resistance and outdoor durability which allows printers to create a multitude of applications, whether they are for indoor or outdoor use.

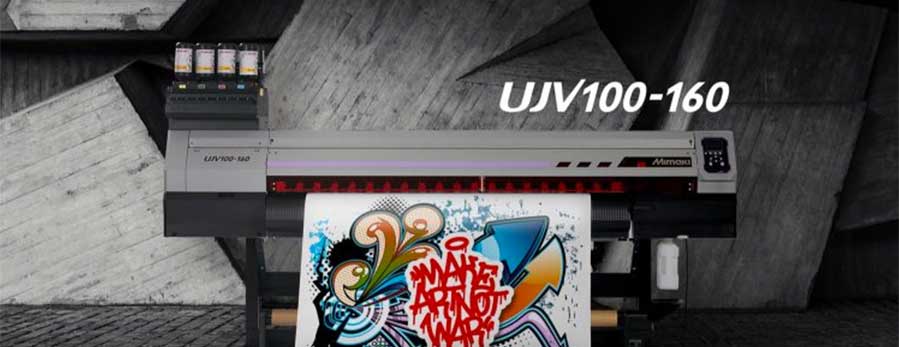

- Mimaki UJV100-160: a roll-to-roll UV printer, the UJV100-160 combines high productivity, extreme versatility, and superior print speed. The printer uses a low-cost UV ink “LUS-190” which cures immediately after being exposed to UV light, enabling a faster turnaround without the need for a degassing period after printing. The LUS-190 ink can be printed onto not only PVC, but also uncoated substrates such as PET film and paper. This system is the ideal solution for print businesses introducing UV printing technology to their production line.

- Mimaki TS100-1600: a dye-sublimation textile printer, the TS100-1600 offers an affordable, high-quality solution to those printers looking to explore digital sublimation printing and expand their production capacity. Featuring a print width of 1,600 mm and speed of 70 m2/h in the fastest mode, the TS100-1600 uses a 1 litre ink bottle which helps reduce the running cost and enables stable, continuous operation due to the reduced need for ink replacement. The TS100-1600 is ideal for a diverse range of applications in fashion, soft signage, home and interior, sportswear, and personalised items.

As part of the company’s long-term commitment to drive innovation in the digital printing space, Mimaki will also introduce two brand-new printing platforms at virtual drupa. Featuring cutting-edge capabilities to print special formats and onto special substrates, the new cutting-edge additions are designed to open new application opportunities in the large format and fashion industries. Mimaki’s experts will also be on hand to provide an insight into the company’s full colour 3D printing technology and relevant application opportunities.

“By showing our extensive portfolio of cutting-edge technologies at virtual drupa, we aim to demonstrate our clear commitment to the industry. Leveraging our flexibility, forward-thinking approach, and R&D expertise, we are able to adapt quickly to market changes and address new customer opportunities to deliver constant system improvements or brand-new innovations,” comments Drion. “The ‘100 Series’ excels when it comes to efficiency and high-quality, while also offering flexibility to produce a wide array of applications, from vibrant wallpapers to high-quality signboards. Further to that, the new additions to be unveiled at the show will break new boundaries in their market segments.”