#Composites

Hexcel highlights innovative composite & lightweight aerospace solutions at ILA Berlin 2024

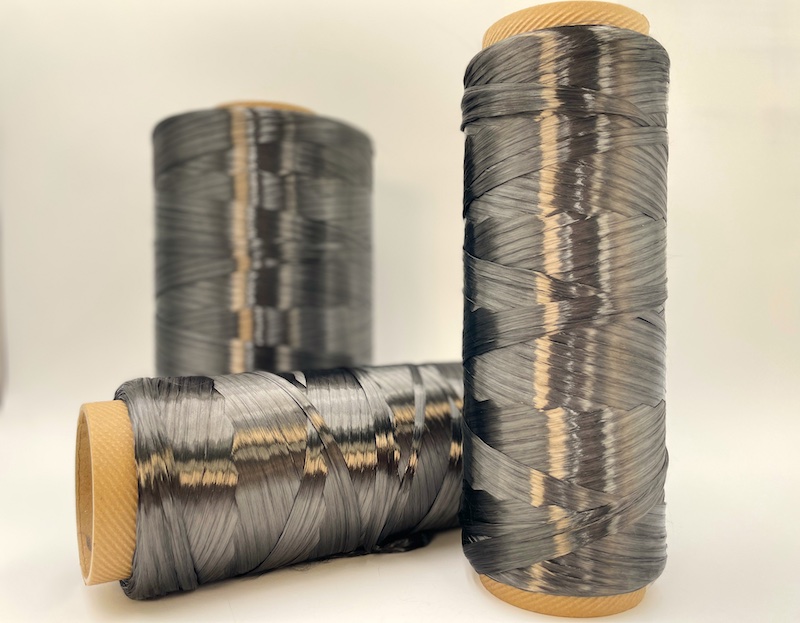

Visitors to ILA Berlin will see the recently launched HexTow® IM9 24K fiber that provides a reliable solution for manufacturers seeking to maximize production efficiency in primary and secondary aerospace structures. HexTow IM9 24K delivers high fiber performance, translating into increased composite tensile strength and offering increased fiber line throughput and productivity provided by a 24K tow size. HexTow IM9 24K builds on the proven legacy of Hexcel intermediate modulus aerospace fibers and delivers a strong value proposition when compared to other commercially available 12K IM fibers.

Hexcel will also present customer solutions developed with HexPly® prepreg materials including an aileron demonstrator developed by Turkish Aerospace for Airbus. This part uses Hexcel HexPly M21E with HexTow IMA carbon fiber and the SQRTM production process. This press molding process reduces cycle time versus autoclave parts and allows manufacturers to work with existing qualified prepreg systems.

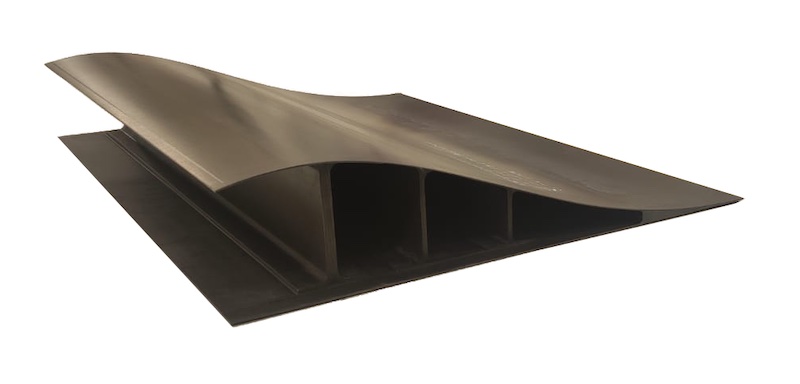

Hexcel will also display thermoplastic solutions co-developed with Arkema at ILA Berlin, highlighting the cost and time reduction benefits that this out-of-autoclave technology can offer for high-rate composite production. Hexcel will present a new HAICoPAS demonstrator panel manufactured using new thermoplastic and carbon fiber materials that target the low-cost assembly of structural aerospace parts. This project has involved Hexcel, Arkema, Ingecal, Coriolis Composites, Pinette Emidecau Industries, Institut de Soudure and CNRS laboratories (PIMM, LTEN). Lightweight structural thermoplastic composite parts made of HexPly® UD Tape with Kepstan® PEKK / HexTow® carbon were produced and then assembled using innovative welding technology. The demonstrator panel has been made in collaboration with an industrial committee including Airbus, Safran, Daher, Hutchinson and ATC.

In addition, Hexcel continues to develop its offering for future energy applications and will showcase its latest carbon fiber and towpreg materials that enable a transition to lower environmental impact transport. Hexcel hot melt towpreg materials take a first step in reducing environmental footprint, focusing on performance optimization and overall reduction in composite material usage.

“We are delighted to exhibit at ILA Berlin 2024, with Hexcel presenting the latest innovations in lightweight composite technology and sustainability for the Aerospace sector,” said Thierry Merlot, Hexcel President – Aerospace for Europe, MEA/AP & Industrial. "ILA Berlin shares our passion for pioneering aerospace development as Hexcel expands its collaboration with OEMs and tier suppliers to help create lighter and more efficient structures for future aerospace programs.”