#Composites

Hexcel to celebrate JEC World 60th anniversary with new aerospace and automotive innovations

“JEC World 2025 promises to be an extraordinary event. We look forward to celebrating the 60th Anniversary of JEC with new innovations and by highlighting the achievements our customers continue to realize with Hexcel materials,” said Thierry Merlot, Hexcel President – Aerospace for Europe, MEA/AP & Industrial. “This event remains an essential forum for deepening our technical collaborations and reaffirming our dedication to driving innovation in lightweight aerospace and automotive composites.”

Aerospace

Responding to Aerospace industry targets for faster production rates, several key Hexcel aerospace technologies are now configured for automation and out-of-autoclave (OOA) production.

HexPly® M51 is a new, rapid-curing prepreg developed for hot-in/hot-out press curing of structural composite parts. In addition to shorter curing cycles, HexPly M51 also reduces the requirement for multiple sets of tooling and labor compared with traditional prepreg systems. Fully compatible with automated tape laying (ATL), automated fiber placement (AFP) and pick-and-place processes, HexPly M51 can help OEMs meet future production targets without compromising on material performances.

HexTow® continuous carbon fiber remains the preferred solution for advanced aerospace applications. Using HexTow IM9 24K manufacturers have an alternative solution to maximize efficiency in primary and secondary aerospace structures. HexTow IM9 24K delivers a strong value proposition when compared to other commercially available IM fibers and compliments the additional standard, intermediate and high modulus fibers in the HexTow range.

Hexcel will promote its TowPlyTM towpreg range for filament winding applications. The combination of fast cure and high temperature resistance resin M901 with intermediate modulus IM 24K and 12K carbon fibers make TowPlyTM a perfect solution for filament winding demanding applications in Defence and Space, urban air mobility (UAM), civil aircraft markets.

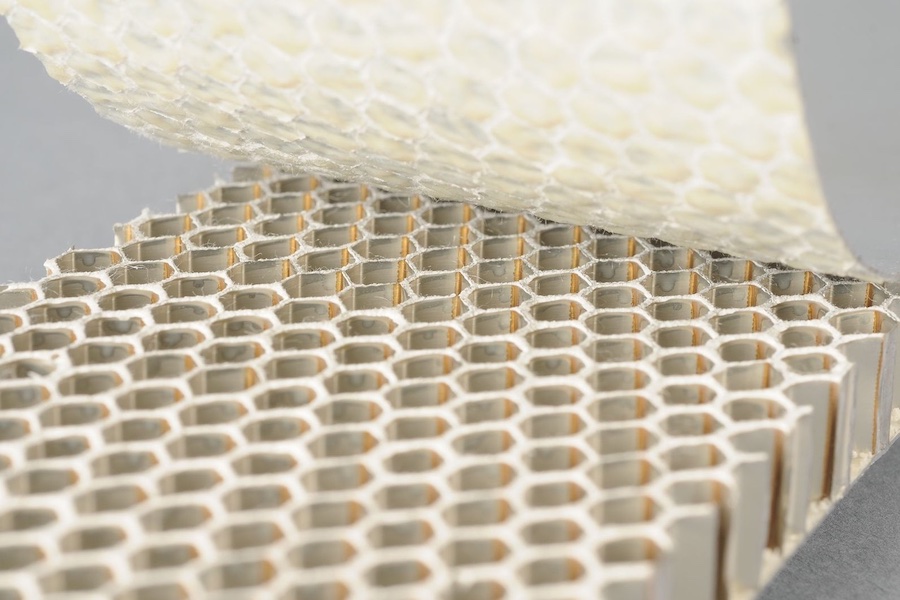

Hexcel has also recently expanded its core portfolio, adding the non-metallic Flex-Core® HRH-302 mid-temperature product to its honeycomb range. Developed to offer a thermal management solution to the aerospace industry, HRH-302 is highly conformable and well suited to the complex curvatures and increasing heat loads found in next-generation aircraft nacelles. Certification is currently underway with Hexcel expecting this material to be a key enabler in future urban air mobility (UAM) and engine programs.

Hexcel will also showcase how its latest Liquid Compression Molding (LCM) products can deliver impressive mechanical performance in structural aerospace components produced with infusion, RTM or C-RTM processes without the investment in autoclaves. HiFlow® 1078-1 epoxy resin, in combination with HiTape® high-performance carbon reinforcement and HiMax® carbon non crimp fabrics, provides a cost-effective OOA process route for primary aircraft structures. Specially developed for continuous mixing processes, the resin can be accurately monitored by in-line mixing equipment thanks to optimized viscosity at process temperatures.

New HexShapeTM, a range of 3D shaped textiles to meet market demand for complex parts. These textiles can be made from various raw materials such as carbon, quartz and glass and can be used in a HexPly® format or in combination with HiFlow® liquid resins.

Hexcel will feature its HexBond® adhesives range in a dedicated zone at JEC World. This range gathers the whole scope of adhesives formats (such as adhesive films, pastes, primers and surface films including M98 & others) that complete the global composite package Hexcel provides. Hexcel sees a strong integration of its adhesives in a number of new and legacy aerospace programs and consolidates its leadership position in the market by offering an adhesive range completely compatible with HexPly® prepregs, delivering proven, long-lasting reliability and outstanding mechanical performance.

Other Aerospace highlights will include:

• An aerospace demonstrator component manufactured with the latest generation of lightweight UD PEKK/carbon thermoplastics. The HELUES project featured partners Christian Karl Siebenwurst GmbH & Co. KG, New Materials Bayreuth GmbH, Airbus Helicopters Deutschland and Hexcel and has developed a novel process to create an A320 door component using a unidirectional single layer of PEKK/carbon and a one-step over molding of PEKK/carbon ribs in just 4 minutes.

• HexPly M51 parts developed by GKN and Duqueine Group

• A HexPly M91/IM8 propeller blade manufactured by FACC for the Archer eVTOL aircraft

• A HexFlow® RTM HF640 gutter component and a HiTape®/HiFlow®1078-1 component created for the NEWS project.

Automotive

For the Automotive industry, Hexcel will launch its new HexPly® M949 cosmetic finish prepreg that has been formulated to provide interior and exterior carbon parts completely free of white spots and surface pinholes. Its long out-life, toughened epoxy matrix meets automotive cosmetic quality targets after autoclave or press molding cure, with components delivering a 150?C Tg without post curing. HexPly M949 is available in a range of traditional automotive fabric styles and is fully compatible with HexPly® XF3 surface film for painted parts. Hexcel will allow viewers to observe the perfect surface finish achieved on a carbon look automotive part demonstrator.

Hexcel continues to embrace the challenge to develop more sustainable materials and will show a HexPly product that uses recycled carbon fiber veil (rCF) to optimize a molded component’s surface finish whilst also significantly reducing the environmental impact of the part.

Visitors to the Hexcel booth will also see an engine sleeve that has been filament wound for electric vehicle specialist RIMAC using TowPlyTM towpreg made with intermediate modulus IM10 carbon fiber. The superior strength of IM10 carbon fiber allows end users to increase the efficiency of high-speed e-engines. In addition, Hexcel will display a range of PrimeTex® and HiMax® reinforcements that are used in a range of automotive structural and aesthetic applications.