#Composites

Toray becomes joint winner in Japan’s Sixth Infrastructure Maintenance Awards

This technology eliminates the need for special jigs and methods in replacement work by reinforcing pitted and corroded pipes. It can thus reduce lead times for strength assessments and cut construction costs. Another key factor in receiving this award was the broad social benefits that could accrue from applying this technology to steel-framed buildings and other structures.

The Infrastructure Maintenance Awards recognize outstanding initiatives and technology developments related to social infrastructure maintenance in Japan at facilities under the jurisdiction of a range of government bodies. These are the Ministry of Land, Infrastructure, Transport and Tourism, the Ministry of Internal Affairs and Communications, the Ministry of Education, Culture, Sports, Science and Technology, the Ministry of Health, Labor and Welfare, the Ministry of Agriculture, Forestry and Fisheries, the Ministry of Economy, Trade and Industry, and the Ministry of Defense. Experts from a range of fields screen candidates for the Minister of Economy, Trade and Industry Award, the Special Award, and the Award for Excellence.

The awards debuted in 2016 to foster Japan’s maintenance sector and recognize best practices among businesses, organizations, researchers in that field.

Award details are as follows.

1. Minister of Economy, Trade and Industry Award

For the development of a CFRP technique employing in-situ VaRTM technology to repair steel pipe corrosion on transmission towers

2. Joint recipients

Tokyo Electric Power Grid, Yasuda Seisakusho, and Toray

3. Award-winning technology

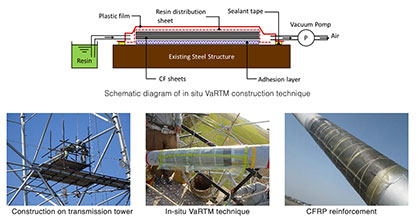

This patented in situ VaRTM technology entails placing CF sheet “TORAYCA® CF fabric” on a steel structure requiring repair, applying a film over the sheets, using a pump to create a vacuum, and injecting and curing epoxy resin. Over time, internal corrosion causes pitting and wall thinning on the steep piping of transmission towers. The conventional repair process is very labor-intensive and expensive, as it entails replacing these pipes. The three companies jointly developed a CFRP repair technique that applies in-situ VaRTM technology to corroded steel pipes that normally need replacing. This setup eliminates the need for special jigs and methods in replacement work, and can reduce lead times for strength assessments and cut construction costs.

4. Progress and potential

Applications to date for in situ VaRTM to repair steel infrastructure have included transmission towers in Japan and floating production storage and offloading facilities overseas. Work is under way extend applications to repair and reinforce steel bridges, steel-framed buildings, and other structures. Toray will keep striving to create technologies and build a value chain in which TORAYCA cloth can significantly extend the service lives and resiliency of domestic and overseas infrastructure.