#Associations

Tracing production costs and carbon footprint in the primary textile industry

This edition of the IPCC covers cost data for the year 2023. Given the high level of expertise and detailed industry input required to produce the report, the process was extended to allow for the necessary engagement of industry specialists under exceptionally demanding conditions in the last two years.

This extended timeline eventually provided an opportunity to deepen the analysis as the report now includes Uzbekistan and introduces a detailed calculation of the carbon footprint associated with each textile product covered, assessed across the full value chain. The report still presents comparative insights on cost structures, covering cost factors, manufacturing costs, and total production costs, across the spinning, draw texturing, weaving, knitting, and finishing segments.

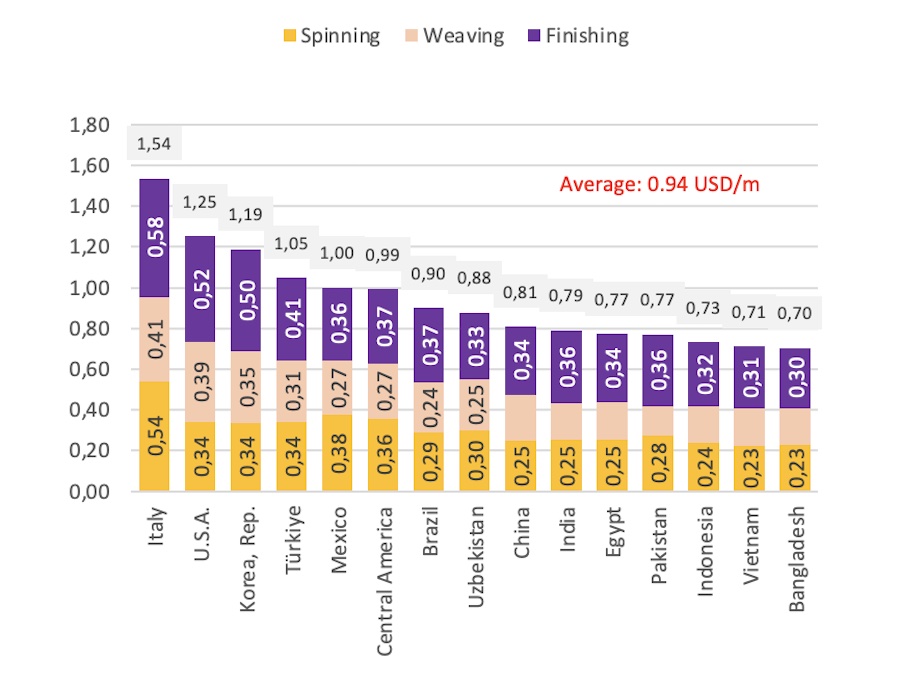

For example, the publication reveals that producing one meter of woven fabric from cotton 1-1/8" in a continuous open width process (COW) in the controlled condition of the study cost 0.94 USD/m on average in 2023 (see Figure 1, amounts exclude raw material cost and range between 0.70 UDS/m in Bangladesh and 1.54 USD/m in Italy). Spinning the yarn required for this meter of finished fabric cost 0.31 USD/m on average (range between 0.23 USD/m in Bangladesh and 0.54 USD/m in Italy). Weaving this yarn added an extra 0.25 USD/m the average production cost of the fabric (range between 0.14 USD/m in Pakistan and 0.41 USD/m in Italy). Finally, finishing this meter of woven fabric increased the final production cost by 0.38 USD/m on average (range between 0.30 USD/m in Bangladesh and 58 USD/m in Italy).

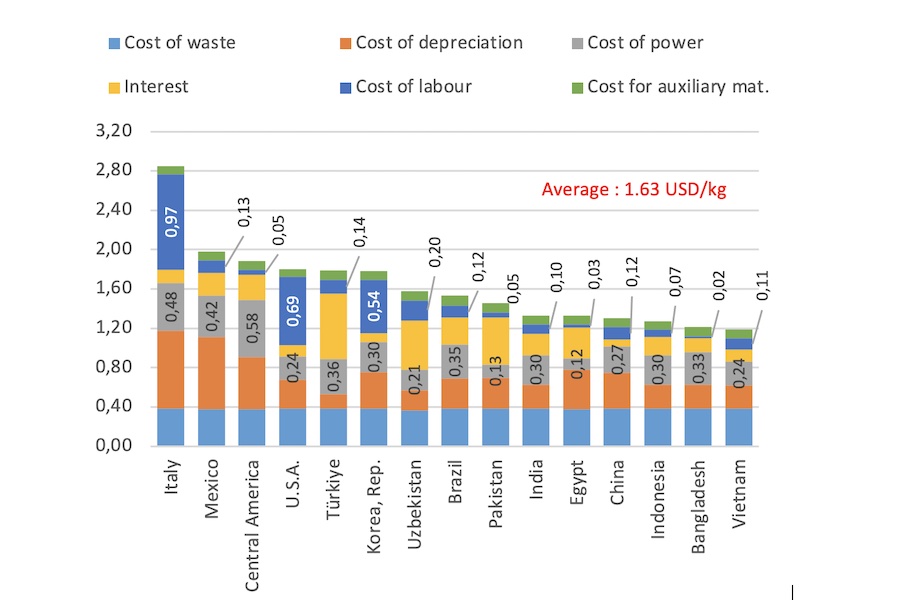

The publication also shows that spinning 1 kg of ring yarn NE/30 in the same controlled conditions cost 1.63 USD/kg on average in 2023, with wide differences amongst countries. This cost was 1.19 USD/kg in Vietnam and reached 2.85 USD/kg in Italy, at the top of the list (see Figure 2). The cost of labor was also highest in Italy (0.97 USD/kg), followed by the USA (0.69 USD/kg) and Korea (0.54 USD/kg). In contrast, labor costs were below 0.10 USD/kg in Indonesia (0.07 USD/kg), Egypt (0.03 USD/kg), and Bangladesh (0.02 USD/kg). The cost of power was higher in Central America, Italy, and Mexico (0.58, 0.48, and 0.42 USD/kg, respectively) and was below 0.20 USK/kg in Pakistan (0.13 USD/kg) and Egypt (0.12 USD/kg).

![Figure 3: Country-specific Carbon Footprint [kg CO2e/kg tex] for producing 1 meter of finished cotton woven fabrics (CO - Woven - Continuous Open Width - COW), by process © 2025 ITMF Figure 3: Country-specific Carbon Footprint [kg CO2e/kg tex] for producing 1 meter of finished cotton woven fabrics (CO - Woven - Continuous Open Width - COW), by process © 2025 ITMF](https://texdata.com//content/texdata-itmf-tracing_production_costs_carbon_footprint-1-900.jpg)

The carbon footprint analysis for woven fabrics finished using continuous open width (COW) processes also reveals significant variation across countries, reflecting differences in energy efficiency, production technologies, and energy sources. Among all countries studied, India reports the highest total carbon footprint, with combined emissions from spinning, weaving, and finishing reaching over 12.5 kg CO?e per kg of textile, driven particularly by high-intensity spinning (4.4 kg) and weaving (4.3 kg) stages. China also ranks among the highest emitters, notably in the finishing stage (3.9 kg), highlighting the energy demands of downstream processing. In contrast, Brazil stands out with the lowest total carbon footprint, at just under 4 kg CO?e per kg, benefiting from low-emission spinning and weaving processes, supported by its renewable energy mix. The United States and Italy also demonstrate relatively low emissions in the early stages of production, reflecting advanced process efficiencies. The newly added Uzbekistan enters the comparison with moderate emissions across all segments, showing potential for improvement in line with global best practices. These findings underscore the critical role of energy source and process optimization in reducing the environmental impact of textile production.

Find more about this extensive study and the reference products—such as NE?30 ring yarn, textured polyester yarn, woven and knitted fabrics, and various cotton and polyester finishing processes—on www.itmf.org/publications.