#Additive Manufacturing

Added value through addition

‘Additive manufacturing in the textile industry’ symposium shows new ways to new products, 17.11.2022 in Obertshausen

Additive manufacturing and its potentials for the textile industry are set to be the focal points of the ‘Additive Manufacturing in the Textile Industry’ symposium, which for years has been organised by the KARL MAYER GROUP in cooperation with the textile research institutes Sächsisches Textilforschungsinstitut e.V. and Textilforschungsinstitut Thüringen-Vogtland e.V. The event will be showcasing the innovative production methods along with their applications in research and industry from various different perspectives.

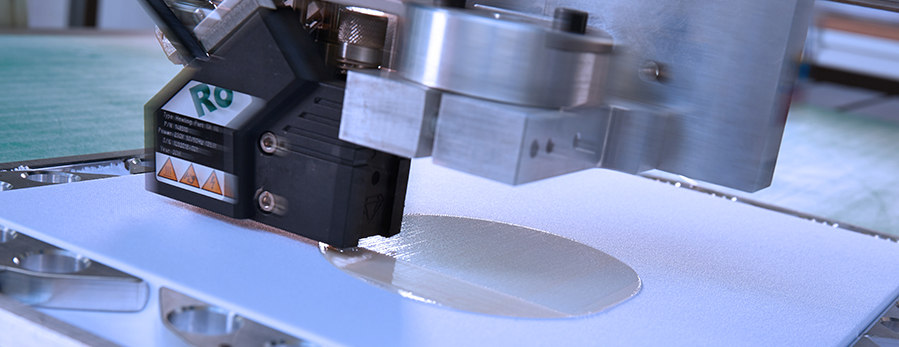

The countdown to the event on 17 November 2023 is now on, with the fifth symposium on additive manufacturing taking place in the company headquarters of KARL MAYER GROUP in Obertshausen once again. KARL MAYER co-organiser Michael Kieren is looking forward to a broad exchange of information between designers, technology experts and product developers alike. “3D printing allows us to completely rethink our whole approach to textile product design. The world of sportswear is already showing us what strides can be made, with mass-produced articles complete with 3D-printed branding and functional elements already firmly established in this domain,” notes the expert. Symposium guests can already look forward to a very special innovation in the form of a technological solution for combining textile manufacturing with 3D printing in the roll-to-roll process. This new development already enjoyed a successful premiere at the Techtextil Trade Fair in Frankfurt am Main.

In addition to the live demonstration of the inline 3D printer, guests can enjoy an exciting guided tour of KARL MAYER and exclusive technical lectures, including presentations by 3D printer manufacturers and companies that already work with additive manufacturing processes. The presentations involve the latest developments in FDM, dispenser, SLA, TFP, and inline processes and materials, as well as applications for auxetic textiles, privacy cover and fashion.

Registration for the live event is now open at:

https://www.titv-greiz.de/de/akademie/workshops/anmeldeformular-workshop/view/form