#Yarn & Fiber

Teijin develops industry's thinnest level gas-diffusion layer for smaller and more functional fuel cells

The GDL is a component used inside a fuel cell to supply hydrogen and oxygen, collect electrons generated by the chemical reaction of the electrodes, and drain water generated in the process.

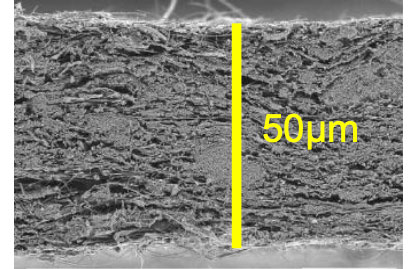

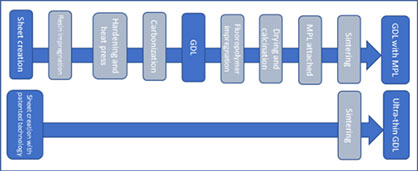

The GDL's microporous structure incorporates Teijin’s PotenCia® fine carbon fiber and Twaron® para-aramid fiber, which are combined in a manufacturing process that has been sped up by deploying proprietary paper-making technology. PotenCia® enables the new GDL to achieve excellent conductivity without damaging the catalyst layer inside the fuel cell while Twaron® contributes to high durability and water repellency. As a result, a conventional microporous layer (MPL) is not required, allowing the new GDL to be slimmed down to 50 micrometers, which is less than half the thickness of a conventional GDL. The new GDL is also expected to reduce production costs by shortening the manufacturing process as well as reducing the number of raw materials required.

Teijin is now verifying the GDL's gas diffusion and thermal conductivity, both indispensable for high performance, and also its contribution to reduced environmental impact. Concurrently, Teijin plans to develop new materials that could use the GDL, such as electrode films, in partnership with other companies that share Teijin's vision for achieving smaller and more functional fuel cells.

Teijin leveraged its extensive experience with fiber-processing technology to develop PotenCia®, an ultrafine fibrous carbon featuring long fibers and high crystallinity. To take advantage of the carbon's thermal conductivity and other special properties, Teijin focused on the possibility to realizing an extra-thin GDL for fuel cells. GDLs usually comprise a conductive fiber sheet made of durable carbon, which is combined with a water-repellent MPL that prevents the accumulation of water but increases the GDL's thickness, thereby lowering the fuel cell's power performance while adding to the manufacturing cost.

The new GDL will be showcased (Booth 1-40) at the FC Expo, which will take place at Tokyo Big Sight from March 15 to 17.

Going forward, Teijin expects to strengthen its development of high-performance materials and solutions for advanced fuel cell products under the company's long-term vision of becoming a company that supports the society of the future.