#Yarn & Fiber

Toray develops ”Ultrasuede™ nu” using 100% plant-based polyester for headrest covers of ANA Green Jet

Ultrasuede™ nu is a non-woven material for a genuine leather appearance with a base material of Ultrasuede™ and a special resin treatment applied to its surface. The latest Ultrasuede™ nu developed by Toray is the first Ultrasuede™ product which partially consists of 100% plant-based polyester for the ultra-fine fibers on the surface of the base material. In addition, about 30% plant-based polyurethane is used inside of the non-woven structure, and about 30% plant-based polyester is used in the reinforcement fabric called scrim, making this developed product the world’s highest level of plant-based raw material content for the non-woven material for a genuine leather appearance. ANA decided to adopt Ultrasuede™ nu because it is the environmentally conscious material that combines luxurious texture, design, and high functionality.

Toray is developing 100% plant-derived polyesters in line with efforts to make its mainline polymers biobased to help materialize a carbon-neutral, circular economy that does not depend on fossil resources.

Since the world's first commercial production of Ultrasuede™, using plant-based recycled resources as part of its raw materials in 2015, we have been focusing on the development of eco-conscious products and will continue to develop products using higher plant-based raw material. Under the Ultrasuede™ vision of “to enrich society through empowered creativity and materials evolution”, we will continue to take on the challenge of realizing Toray Group's corporate philosophy, " Contributing to society through the creation of new value with innovative ideas, technologies, and products”.

Details of “Ultrasuede™ nu” for ANA’s headrest covers

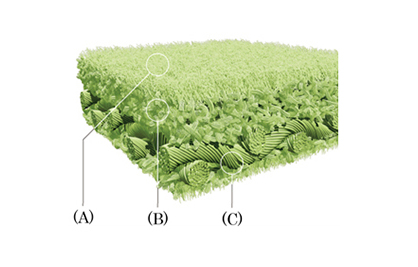

1. Structure

(a) Ultra-fine fibers

The ultra-fine fibers are composed of 100% plant-based polyester made of ethylene glycol from sugarcane molasses byproducts and dimethyl terephthalate from corn starch.

(b) Elastomer (Used inside of non-woven fabric structure)

The elastomer is composed of about 30% plant-based polyurethane made with polyol from castor oil plant.

(c) Scrim

The scrim is composed of about 30% plant-based polyester made from ethylene glycol from sugarcane molasses byproducts.

*The plant-based raw material content in this developed Ultrasuede™ nu is about 64%.

(Based on the results of our internal investigation)

2. Characteristics

• Delicate texture and suppleness reminiscent of premium aniline leather (note 3)

• A unique, calming luster

• Light, comfortable breathability

• Environmentally conscious non-animal (vegan)material (note 4)

Notes

1. 100% plant-based polyester in keeping with ISO 16620-1 3.1.5 biobased synthetic polymer content standard

2. See press release issued on June 3, 2022, titled, ANA to Introduce Special ANA Future Promise Aircraft to Highlight Commitment to ESG

https://www.anahd.co.jp/group/en/pr/202206/20220603.html

3. Aniline leather, which is made by bright dyeing using synthetic dyes (aniline dyeing) and finishing

with transparent resin (aniline finishing) to take advantage of the leather's original delicate grain

surface, is considered one of the most luxurious finishes for leather products.

4. The main components of Ultrasuede™ nu are polyester and polyurethane.

References

Related ANA news release

ANA Green Jet Takes to the Skies This October (October 3, 2022)

https://www.anahd.co.jp/group/en/pr/202210/20221003.html

Ultrasuede™’s sustainability

https://www.ultrasuede.us/sustainability/

Ultrasuede™ nu website

https://www.ultrasuede.us/about/design_technologies/

Ultrasuede™ website

https://www.ultrasuede.us/