#Yarn & Fiber

Lenzing presents its unique environmentally- friendly processes, highlighting top-class TENCEL™ fibers.

Its TENCEL™-branded specialty fibers, dedicated to a variety of highly specialized textile applications, have been long appreciated for their outstanding characteristics – softness, smoothness, luxurious shine and flow – by multiple manufacturing companies that are part of the supply chain, many of which represent the essence of FILO itself, and are the ingredient that has also been featuring in some of the most sustainable collections in the world.

- Lenzing Group is at FILO zooming in on its one-of-a-kind sustainable approach and on a selection of key innovations, which are on display as part of the space dedicated to Cittadellarte – Fondazione Pistoletto.

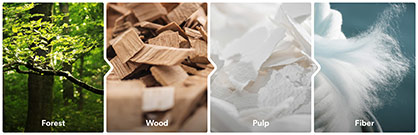

- TENCEL™ fibers have long been appreciated for their outstanding quality and performance but also for their unmatched production process: the Group operates two commercial-scale pulp biorefineries ensuring 100% wood utilization to produce fibers, bio-based chemicals, and bio-energy. ?

- ?High efficiency, recovering, reusing, saving: the biorefinery concept minimizes waste and represents the biological cycle of the circular economy idea. ?

As part of the space dedicated to Cittadellarte – Fondazione Pistoletto and Fashion B.E.S.T., the first Italian collective of responsible fashion designers, a selection of TENCEL™’s key technologies will be under the spotlight:?

- TENCEL™ x REFIBRA™, using cotton textile waste and wood pulp as the feedstock for cellulosic fibers, creating a circular solution;

- TENCEL™ x Indigo Color, infusing pigment into fibers directly during the spinning process;

- TENCEL™ Luxe, providing superior aesthetics, performance and comfort to be the perfect partner of other noble fibers such as silk, cashmere or wool;?

- TENCEL™ Carbon Zero, offering carbon-zero CarbonNeutral®-certified products by Natural Capital Partners;

- TENCEL™ x Eco Clean, bringing totally chlorine-free-bleached TENCEL™ Modal fibers to the textile industry.

Lenzing took to heart its ecological footprint long before the word sustainability was even coined, let alone applied as a concept. An Austrian-based company that has focused on fibers for more than 80 years, its priority has been to produce fibers for many sectors (fashion, beauty care, cleaning, hygiene and home textiles) in a sustainable way. Each Lenzing product is made of cellulose from wood, a renewable natural resource, coming only from certified sustainable sources. An important characteristic of cellulose is its biodegradability and compostability: at the end of their life cycle, cellulosic fibers can re-enter the ecosystem and create a closed loop. Lenzing’s production process itself mirrors the circular concept of nature: water and chemicals are re-used over and over, re-circulated within the system.

The Lenzing Group operates two commercial-scale biorefineries with 100% wood utilization, which ensure that the totality of wood constituents are used to produce fibers, biobased chemicals, and bioenergy, thus maximizing value creation from an economic and environmental perspective. This concept is illustrated by Carlo Covini, Lenzing Business Development Manager Italy & Switzerland, in his presentation “Lenzing’s biorefinery concept” on September 30 at 3 pm at Dialoghi di Confronto – Networking Area. At the heart of the concept is the notion that renewable source material wood is used by Lenzing as universal replacement for non-renewable raw materials, such as crude oil. Therefore, Lenzing aims to utilize and commercialize all of the wood’s natural components by turning them into pulp for Lenzing fibers or other useful Lenzing solutions for various industries.

Its biorefinery products become valuable supplies to the food industry: acetic acid acts as the perfect ingredient to pickle vegetables, and xylose is processed into a low-calorie sugar substitute. The energy contained in the wood is then used to operate Lenzing’s facilities, making them almost fully energy self-sufficient.

“TENCEL™ is produced in Austria in a plant near Attersee, the lake that in the past had inspired personalities like Gustav Mahler and Gustav Klimt. It is located in a characteristic landscape, with a natural environment to safeguard. For this reason, already in the Seventies Lenzing gave great attention to the resources used and the emissions produced, by implementing sustainable strategies.” says Carlo Covini, Lenzing Business Development Manager Italy & Switzerland. “We are honored to present to the industry our innovative processes and solutions, as we truly believe they raise the bar of sustainability helping to make a real difference when it comes to reducing our impact on the planet.”