#INDIA ITME 2022

Itema exhibits its latest innovations and a complete range of weaving solutions at India ITME 2022

Itema comes from an outstanding year in terms of sales of weaving machines in India. The company closed in fact an impressive number of deals providing the Indian textile industry with its advanced weaving technology to weave a wide range of fabrics.

As stated by Sameer Kulkarni, Itema Weaving India General Manager Sales, “2022 represents a landmark year for Itema in India. We are proud to see how our weaving technology is nowadays recognized as the most versatile and the most reliable in terms of textile mastery and performances. In 2022,” continued Kulkarni “we established a new record: Itema is by far the best selling supplier of high-end rapier weaving machines in India.”

This success is largely due to the Itema leadership of the Surat Region, where weavers selected the Itema rapier weaving machines R9500-2 and R9000-2 as their preferred option when it comes to weaving sophisticated fashion apparel and sarees fabrics. Both with dobby and Jacquard shedding, the Itema rapier technology demonstrated in fact its superior performances in terms of fabric quality and insertion of fancy yarns.

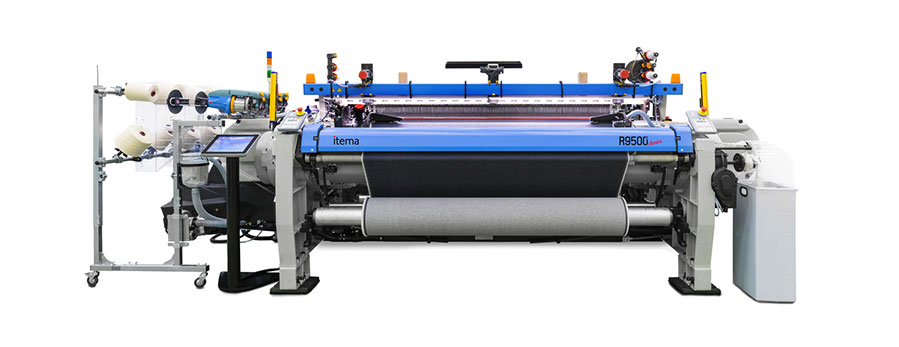

At India ITME 2022, Itema will showcase a racehorse in its rapier technology portfolio, the R9500-2denim. The weaving machine on show will be equipped with the one-of-a-kind iSAVER®, the device developed by Itemalab® that by eliminating the waste selvedge on the left-hand side of the fabric allows never-before- seen raw materials and economic savings. iSAVER® established a new benchmark in the weaving industry and today it represents the only device effectively running in real weaving conditions capable to contribute to a sustainable weaving process.

Moreover, an Itema rapier R9500-2 in Jacquard version and weaving furnishing fabrics will be exhibited in partner booth Bonas, Hall 14A – Booth 2B1.

In the words of Ugo Ghilardi, Itema Group CEO “we are excited to be finally back at India ITME 2022. India is a key market for Itema and we really value our Indian customers. Our target is much more than selling our weaving machines, we aim at creating long-lasting partnerships built on mutual success.”

Itema is present in India with a fully-operational branch since 2003, counting more than 50 employees, with sales and after-sales teams, technical support and advanced repair centers to ensure the highest possible standard of weaving solutions, with a complete offering and range of services to its valuable Customers in the Indian market.

Itema is a trusted partner of many Indian weaving mills, from large textile conglomerates to smaller textile manufacturers, providing the most advanced and user-friendly weaving technology and real-time assistance, from the initial negotiation stage and throughout the whole machine life cycle.

The Itema staff will be present at India ITME 2022 to welcome customers and partners to illustrate the latest innovations and the full range of weaving solutions supplied by Itema, including OEM spare parts of Itema and previous brands and Schoch reeds and other accessories range.

Visit us at India ITME 2022 in Hall 15, Booth C5D6.