#Weaving

Itema Group announces the closing of the acquisition of PTMT (ex Panter)

Despite the difficult moment that the world economy is going through due to the consequences of the pandemic generated by the COVID-19 virus, Itema’s Board of Directors chooses not to stop investments, convinced that the only way to overcome this critical period is to believe in a future made prosperous by long-term strategic choices.

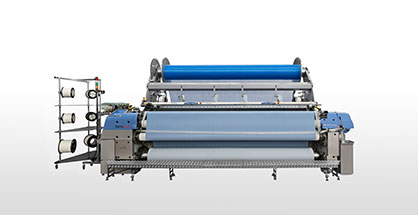

The acquisition by its subsidiary Itema Tech s.r.l. allows Itema to expand its product portfolio by adding PTMT technology, with the aim of consolidating and establishing a new leadership in the field of technical fabrics.

The launch of Itematech, the new division dedicated to technical textiles,in the first quarter of 2019, gathered growing interest from weavers all over the world. Itematech, indeed, offers today the most complete technological portfolio available on the market to weave these special fabrics.

The operation confirms Itema’s Board Directors intention to invest in the textile machinery sector, as witnessed by the words of Mr. Gianfranco Ceruti, President of the Board of Directors of Itema: "the acquisition of PTMT enriches Itema’s technological offer for weaving machinery, adding even more value to our Company's proposal to the market".

We are therefore confident that the merger of PTMT's deep technological know-how and the structural and organizational solidity of our Group will give rise to new opportunities for development and affirmation on international markets".

Mr. Ugo Ghilardi, CEO of Itema Group, commented as follows: “Technical fabrics represent an extremely valuable and complex market in the global textile scenario, constanlty evolving and growing. With Itematech we are ready to respond to the needs of this specific sector, through the widest range of technological solutions offered by a single partner. Itematech will be able to count on Itema Group's production capacity and ist commercial and service network, along with the technological solutions that have always been the flagship of the Panter brand, such as the loom dedicated to weaving carbon fiber, in what is a unique synergy on the market ".

The Itema plant in Colzate, at the forefront in the field of lean manufacturing, was quickly equipped by the Itema engineering team for the production of the ex-Panter models thus guaranteeing the high quality standards of Itema weaving machines. Thanks to the union of the two technological realities, Itematech guarantees the weaving of the widest range of technical fabrics - from carbon fiber to the coarsest and finest filter fabrics, to name just a few - and the widest know-how in the sector.