#Textile processing

KSL Joining Technology GmbH: new company to strengthen high-tech textile solutions

KSL Joining Technology GmbH officially established

As of February 26, 2025, all KSL activities will be conducted under the newly founded KSL Joining Technology GmbH, headquartered in Bensheim, Germany:

KSL Joining Technology GmbH

Bertha-Benz-Straße 4, 64625 Bensheim, Germany

Tel.: +49 (0) 6251 9620-0

The transition aims to increase market visibility, drive technological advancements, and provide faster and more efficient solutions for customers and partners.

Focus on automation and process optimization

KSL remains committed to state-of-the-art robotics and control technology, enabling customers to automate both partial and complete processes while minimizing operator intervention. This ensures:

+ Higher productivity

+ Greater process reliability

+ Seamless automation in textile and composite manufacturing

Continuing partnership

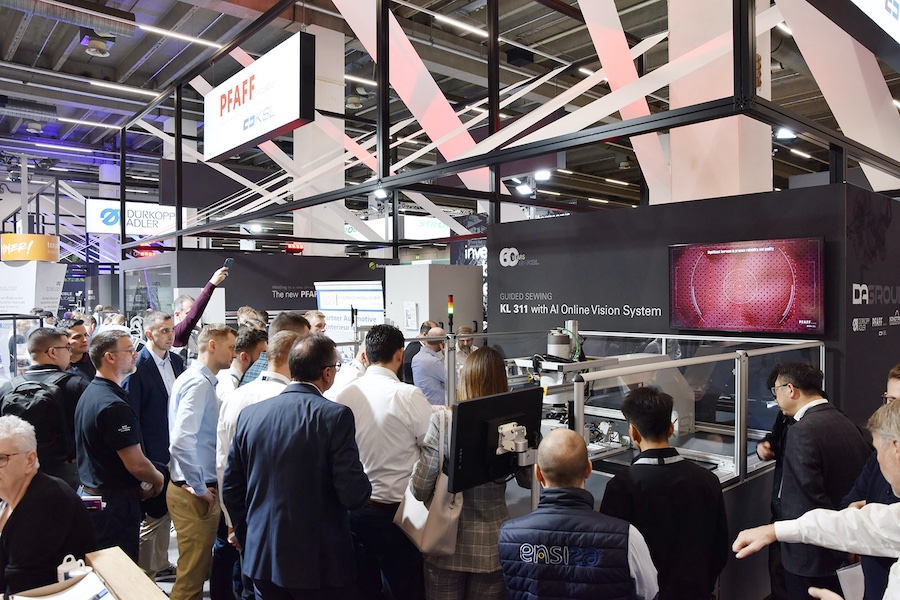

The restructuring does not impact PFAFF Industriesysteme und Maschinen GmbH, to which KSL previously belonged. Moving forward, both KSL Joining Technology GmbH and PFAFF Industriesysteme und Maschinen GmbH will operate as 100% subsidiaries of the SGG Group, under the umbrella of the Dürkopp Adler Group.

Driving the future of high-tech textile solutions

With this transformation, KSL is positioning itself for further growth and technological leadership in the highly dynamic textile industry. The company looks forward to continuing its commitment to innovation, precision, and automation, shaping the future alongside its global customers and partners.