#Yarn & Fiber

Covestro and Genomatica produce important chemical raw material using biotechnology

Material manufacturer Covestro and biotechnology pioneer Genomatica announced an important industry milestone to advance sustainability resulting from their partnership. The two companies have teamed to be the first to successfully produce significant volumes of a plant-based version of the chemical raw material HMDA (hexamethylene diamine).

HMDA, with a worldwide market of 2 million tons per year, is a key ingredient for a widely-used type of nylon (nylon-6,6), as well as an important component for raw materials for coatings and adhesives from Covestro. Up to now, HMDA has been manufactured from fossil feedstocks. Coatings and adhesives can be produced more sustainably thanks to bio-based HMDA, made from renewable feedstocks. Areas of application include automotive, construction, furniture, textiles and fibers.

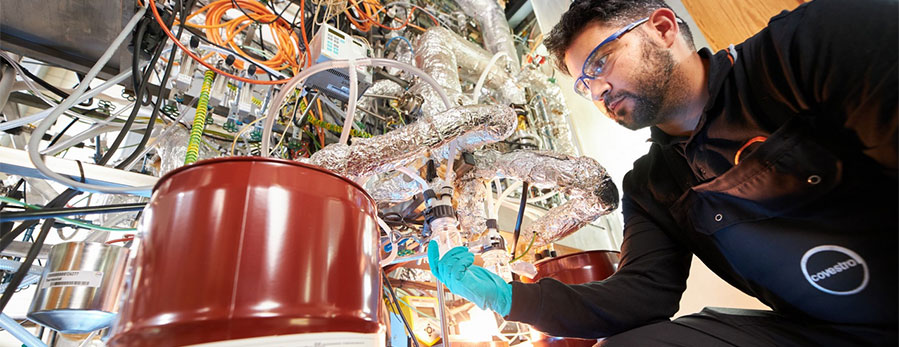

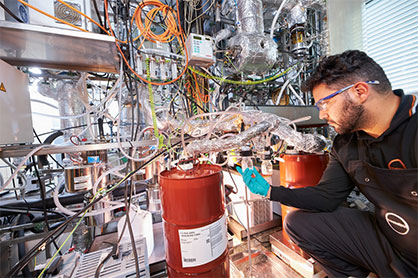

Teams from Genomatica and Covestro have been working together to develop a commercial process technology for bio-based HMDA. The companies expect to produce ton quantities of high-quality material over the course of multiple production campaigns. Both partners are already processing and testing material from their initial production campaigns, and the resulting bio-HMDA is of high purity and quality. The companies plan to advance the program to full commercial scale, and Covestro has secured an option from Genomatica to license the resulting integrated GENO™ HMD process technology for commercial production.

Genomatica develops widely-used ingredients and materials using biotechnology and renewable, plant-based feedstocks rather than fossil feedstocks and their associated extractive processing methods. These materials are used by brands and their suppliers in popular goods ranging from apparel to cosmetics. Covestro brings extensive know-how in the field of research, chemical process technology and application development. The cooperation for the development of alternative raw materials based on biotechnology advances Covestro’s global program to achieve the circular economy.

Covestro established an R&D Competence Center for biotechnology to further strengthen its overall know-how in this field. Bio-based raw materials and biotechnology have also been identified as one of five focus areas at Covestro´s Venture Capital (COVeC) approach.

"The increased use of alternative raw materials, including the utilization of biotechnology, is an important pillar of our approach to fully embrace the circular economy and help make it a global guiding principle," says Covestro CEO Dr. Markus Steilemann. "Our program with Genomatica, which complements our internal R&D, is one of our largest external funding of biotechnology R&D to date, and underscores both the field’s importance to Covestro and the results it can deliver."

Replacing fossil-based raw materials

"This program is of great importance to us, because markets are increasingly asking for more environmentally compliant products based on renewable raw materials, which are just as powerful as their fossil-based alternatives," says Dr. Thorsten Dreier, global head of the Covestro business entity Coatings & Adhesives. "We can reduce this dependence on fossil feedstocks with innovative technology and our partnership. With a purely plant-based HMDA, we can significantly advance our corporate objective of CO2-neutral production."

"Genomatica is committed to delivering a portfolio of sustainable materials that can help any brand reduce the carbon footprint of its products while maintaining the performance customers count on," said Christophe Schilling, Genomatica CEO. "Covestro is a valued partner that is playing a leading role in improving the environmental impact of many of today’s most prevalent materials. Together, we are taking an important step to reduce greenhouse gas emissions for a broad range of products we use in daily life."